Page 224 - Protec PR Book Volume 2

P. 224

Popular SGM low-profile LED fixtures were also involved in the shape of P5’s for the VIP decks and Q7’s to light up the bars. For the front of the DJ riser, Protec chose 16 Jarag lights, all DMX controllable, so they could be programmed to have words flashing through. This provided an extra dimension to what was already a really well-lit set.

At FOH Protec also placed Clay Paky Scenius Unico fixtures — little spots that served as various lighting positions for the dancers. Finally for the entrance, Protec featured 12 x Clay Paky Super Sharpies to create a welcoming effect, controlled from a ChamSys MagicQ MQ60 desk.

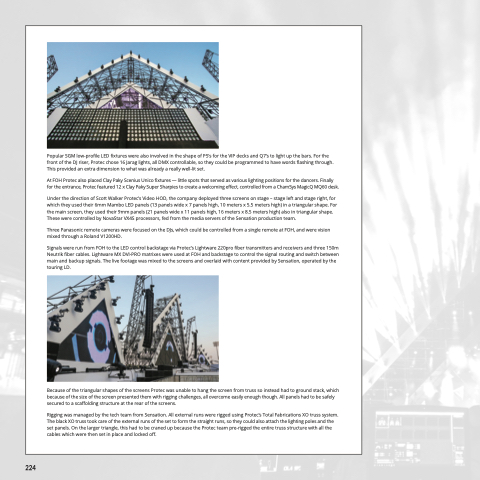

Under the direction of Scott Walker Protec’s Video HOD, the company deployed three screens on stage – stage left and stage right, for which they used their 6mm Mambo LED panels (13 panels wide x 7 panels high, 10 meters x 5.5 meters high) in a triangular shape. For the main screen, they used their 9mm panels (21 panels wide x 11 panels high, 16 meters x 8.5 meters high) also in triangular shape. These were controlled by NovaStar VX4S processors, fed from the media servers of the Sensation production team.

Three Panasonic remote cameras were focused on the DJs, which could be controlled from a single remote at FOH, and were vision mixed through a Roland V1200HD.

Signals were run from FOH to the LED control backstage via Protec’s Lightware 220pro fiber transmitters and receivers and three 150m Neutrik fiber cables. Lightware MX DVI-PRO matrixes were used at FOH and backstage to control the signal routing and switch between main and backup signals. The live footage was mixed to the screens and overlaid with content provided by Sensation, operated by the touring LD.

Because of the triangular shapes of the screens Protec was unable to hang the screen from truss so instead had to ground stack, which because of the size of the screen presented them with rigging challenges, all overcome easily enough though. All panels had to be safely secured to a scaffolding structure at the rear of the screens.

Rigging was managed by the tech team from Sensation. All external runs were rigged using Protec’s Total Fabrications XO truss system. The black XO truss took care of the external runs of the set to form the straight runs, so they could also attach the lighting poles and the set panels. On the larger triangle, this had to be craned up because the Protec team pre-rigged the entire truss structure with all the cables which were then set in place and locked off.