Page 74 - Australian Wood Review №103 2019

P. 74

20

19

21

Always hold the skew with the And finishing is simple; no need for

slope of the edge going in the same sandpaper, just grab a handful of fresh

direction as the curve you are turning, shavings, squeeze them around your

and then as the skew reaches about finished turning and pedal like the

45°, flip the skew over and finish the clappers. The end result is a beautifully

bead with the tip. burnished piece (photos 22, 23).

To smooth any long surfaces, Follow these instructions and you will

use the flat chisel, bevel down, end up with a pole lathe and a turning

and held at an angle to the blank of your own. The first of many as this

where you can imagine the fibres addictive ancient gizmo takes hold of

slicing off the closest corner of your soul. I make spoons and scoops on

the bevel. This one takes a bit of mine these days, but regardless of what

practice and it’s a notorious cause you make it’s doubly satisfying because

of shed based tantrums when it there really are few better feelings than

catches and rips out the fibres. making something from a tool that you

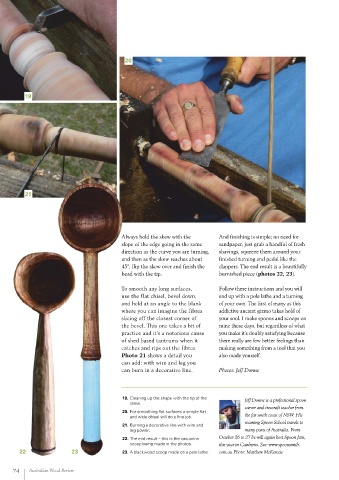

Photo 21 shows a detail you also made yourself.

can add: with wire and leg you

can burn in a decorative line. Photos: Jeff Donne

19. Cleaning up the shape with the tip of the Jeff Donne is a professional spoon

skew.

carver and treecraft teacher from

20. For smoothing flat surfaces a simple flat

and wide chisel will do a fine job. the far south coast of NSW. His

roaming Spoon School travels to

21. Burning a decorative line with wire and

leg power. many parts of Australia. From

22. The end result – this is the casuarina October 26 to 27 he will again host Spoon Jam,

scoop being made in the photos. this year in Canberra. See: www.spoonsmith.

22 23 23. A blackwood scoop made on a pole lathe. com.au Photo: Matthew McKenzie

74 Australian Wood Review