Page 6 - My Report

P. 6

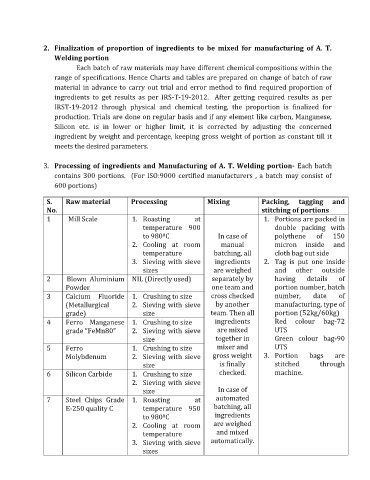

2. Finalization of proportion of ingredients to be mixed for manufacturing of A. T.

Welding portion

Each batch of raw materials may have different chemical compositions within the

range of specifications. Hence Charts and tables are prepared on change of batch of raw

material in advance to carry out trial and error method to find required proportion of

ingredients to get results as per IRS-T-19-2012. After getting required results as per

IRST-19-2012 through physical and chemical testing, the proportion is finalized for

production. Trials are done on regular basis and if any element like carbon, Manganese,

Silicon etc. is in lower or higher limit, it is corrected by adjusting the concerned

ingredient by weight and percentage, keeping gross weight of portion as constant till it

meets the desired parameters.

3. Processing of ingredients and Manufacturing of A. T. Welding portion- Each batch

contains 300 portions. (For ISO:9000 certified manufacturers , a batch may consist of

600 portions)

S. Raw material Processing Mixing Packing, tagging and

No. stitching of portions

1 Mill Scale 1. Roasting at 1. Portions are packed in

temperature 900 double packing with

to 980 C In case of polythene of 150

0

2. Cooling at room manual micron inside and

temperature batching, all cloth bag out side

3. Sieving with sieve ingredients 2. Tag is put one inside

sizes are weighed and other outside

2 Blown Aluminium NIL (Directly used) separately by having details of

Powder one team and portion number, batch

3 Calcium Fluoride 1. Crushing to size cross checked number, date of

(Metallurgical 2. Sieving with sieve by another manufacturing, type of

grade) size team. Then all portion (52kg/60kg)

4 Ferro Manganese 1. Crushing to size ingredients Red colour bag-72

grade “FeMn80” 2. Sieving with sieve are mixed UTS

size together in Green colour bag-90

5 Ferro 1. Crushing to size mixer and UTS

Molybdenum 2. Sieving with sieve gross weight 3. Portion bags are

size is finally stitched through

6 Silicon Carbide 1. Crushing to size checked. machine.

2. Sieving with sieve

size In case of

7 Steel Chips Grade 1. Roasting at automated

E-250 quality C temperature 950 batching, all

to 980 C ingredients

0

2. Cooling at room are weighed

temperature and mixed

3. Sieving with sieve automatically.

sizes