Page 140 - ro membanes

P. 140

6.4 ADDITION OF SCALE INHIBITORS 123 a longer retention time than coagulation. The flocculation systems most widely used for pretreat-

ment of saline source waters are mechanical flocculators with vertical mixers (Fig. 6.2).

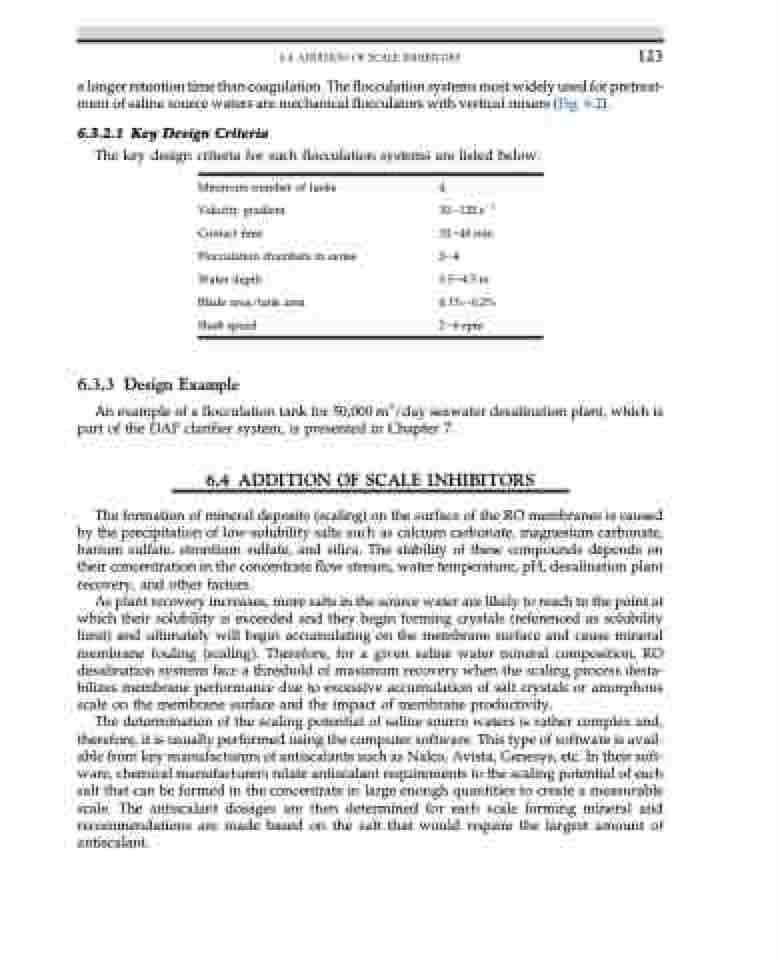

6.3.2.1 Key Design Criteria

The key design criteria for such flocculation systems are listed below:

Minimum number of tanks Velocity gradient

Contact time

Flocculation chambers in series Water depth

Blade area/tank area Shaft speed

6.3.3 Design Example

4

30e120 s1 10e40 min 2e4 3.5e4.5 m 0.1%e0.2% 2e6 rpm

An example of a flocculation tank for 50,000 m3/day seawater desalination plant, which is part of the DAF clarifier system, is presented in Chapter 7.

6.4 ADDITION OF SCALE INHIBITORS

The formation of mineral deposits (scaling) on the surface of the RO membranes is caused by the precipitation of low-solubility salts such as calcium carbonate, magnesium carbonate, barium sulfate, strontium sulfate, and silica. The stability of these compounds depends on their concentration in the concentrate flow stream, water temperature, pH, desalination plant recovery, and other factors.

As plant recovery increases, more salts in the source water are likely to reach to the point at which their solubility is exceeded and they begin forming crystals (referenced as solubility limit) and ultimately will begin accumulating on the membrane surface and cause mineral membrane fouling (scaling). Therefore, for a given saline water mineral composition, RO desalination systems face a threshold of maximum recovery when the scaling process desta- bilizes membrane performance due to excessive accumulation of salt crystals or amorphous scale on the membrane surface and the impact of membrane productivity.

The determination of the scaling potential of saline source waters is rather complex and, therefore, it is usually performed using the computer software. This type of software is avail- able from key manufacturers of antiscalants such as Nalco, Avista, Genesys, etc. In their soft- ware, chemical manufacturers relate antiscalant requirements to the scaling potential of each salt that can be formed in the concentrate in large enough quantities to create a measurable scale. The antiscalant dosages are then determined for each scale forming mineral and recommendations are made based on the salt that would require the largest amount of antiscalant.