Page 71 - ro membanes

P. 71

54

3. DIAGNOSTICS OF MEMBRANE FOULING AND SCALING

20.00 19.67 19.33 19.00 18.67 18.33 18.00 17.67 17.33 17.00 16.67 16.33 16.00 15.67 15.33 15.00

FIGURE 3.13

Weight in kg

18.91

18.56

17.84

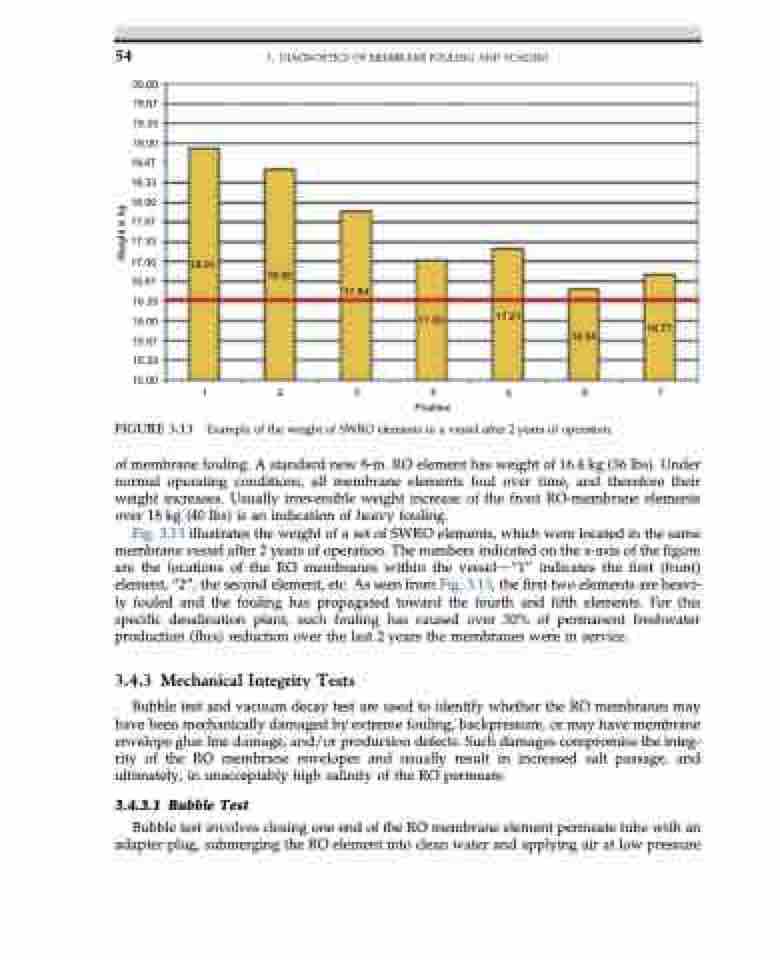

of membrane fouling. A standard new 8-in. RO element has weight of 16.4 kg (36 lbs). Under normal operating conditions, all membrane elements foul over time, and therefore their weight increases. Usually irreversible weight increase of the front RO-membrane elements over 18 kg (40 lbs) is an indication of heavy fouling.

Fig. 3.13 illustrates the weight of a set of SWRO elements, which were located in the same membrane vessel after 2 years of operation. The numbers indicated on the x-axis of the figure are the locations of the RO membranes within the vesseld“1” indicates the first (front) element; “2”, the second element, etc. As seen from Fig. 3.13, the first two elements are heavi- ly fouled and the fouling has propagated toward the fourth and fifth elements. For this specific desalination plant, such fouling has caused over 30% of permanent freshwater production (flux) reduction over the last 2 years the membranes were in service.

3.4.3 Mechanical Integrity Tests

Bubble test and vacuum decay test are used to identify whether the RO membranes may have been mechanically damaged by extreme fouling, backpressure, or may have membrane envelope glue line damage, and/or production defects. Such damages compromise the integ- rity of the RO membrane envelopes and usually result in increased salt passage, and ultimately, in unacceptably high salinity of the RO permeate.

3.4.3.1 Bubble Test

Bubble test involves closing one end of the RO membrane element permeate tube with an adapter plug, submerging the RO element into clean water and applying air at low pressure

17.03

17.21

1234567 Position

Example of the weight of SWRO elements in a vessel after 2 years of operation.

16.54

16.77