Page 72 - ro membanes

P. 72

3.4 MEMBRANE AUTOPSY 55

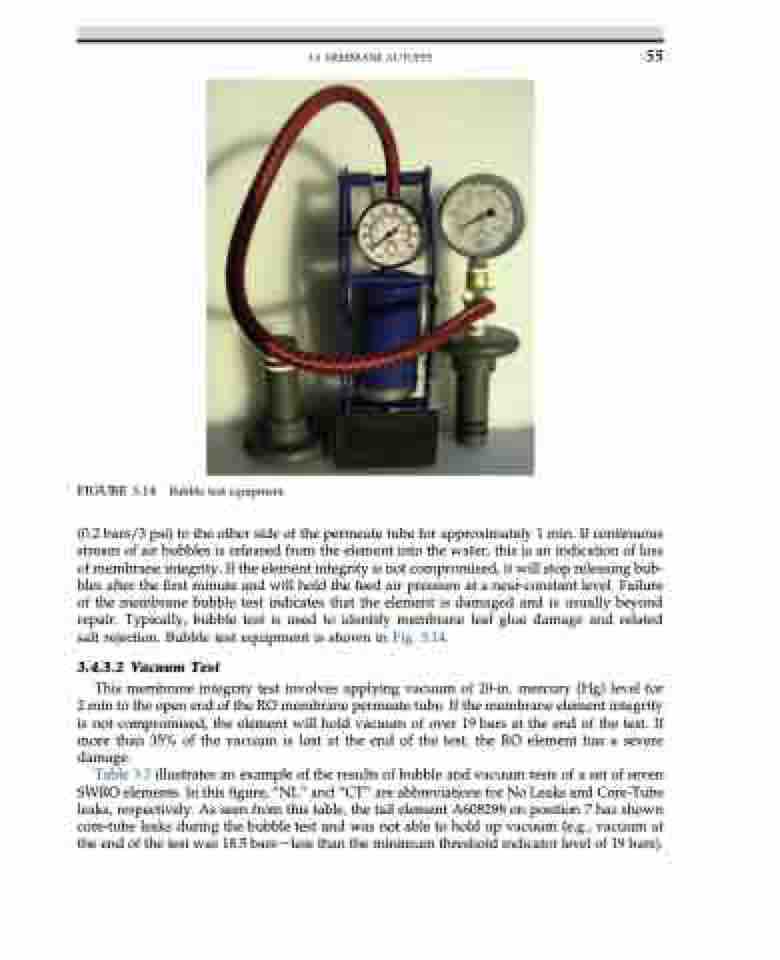

FIGURE 3.14 Bubble test equipment.

(0.2 bars/3 psi) to the other side of the permeate tube for approximately 1 min. If continuous stream of air bubbles is released from the element into the water, this is an indication of loss of membrane integrity. If the element integrity is not compromised, it will stop releasing bub- bles after the first minute and will hold the feed air pressure at a near-constant level. Failure of the membrane bubble test indicates that the element is damaged and is usually beyond repair. Typically, bubble test is used to identify membrane leaf glue damage and related salt rejection. Bubble test equipment is shown in Fig. 3.14.

3.4.3.2 Vacuum Test

This membrane integrity test involves applying vacuum of 20-in. mercury (Hg) level for 2 min to the open end of the RO membrane permeate tube. If the membrane element integrity is not compromised, the element will hold vacuum of over 19 bars at the end of the test. If more than 35% of the vacuum is lost at the end of the test, the RO element has a severe damage.

Table 3.2 illustrates an example of the results of bubble and vacuum tests of a set of seven SWRO elements. In this figure, “NL” and “CT” are abbreviations for No Leaks and Core-Tube leaks, respectively. As seen from this table, the tail element A608298 on position 7 has shown core-tube leaks during the bubble test and was not able to hold up vacuum (e.g., vacuum at the end of the test was 18.5 barsdless than the minimum threshold indicator level of 19 bars).