Page 139 - PPAP submission requirements (PPAP check sheet)

P. 139

Form 13.3

PAGE _1_/_2_

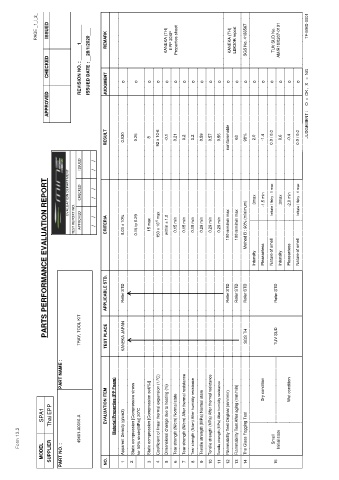

MODEL SPA1 PARTS PERFORMANCE EVALUATION REPORT

SUPPLIER Thai EPP APPROVED CHECKED ISSUED

PART NO. : PART NAME :

49401-A0010-A TRAY, TOOL KIT REVISION NO. : ______1_______

ISSUED DATE : __28/1/2020___

NO. EVALUATION ITEM TEST PLACE APPLICABLE STD. CRITERIA RESULT JUDGMENT REMARK

Material Properties (PP Foam)

1 Apparent Density (g/cm3) KANEKA JAPAN Refer STD 0.03 ± 10% 0.030 o

2 Static compression [Compressive stress

๐

for 50% strain(MPa)] 20 C 0.15 to 0.29 0.25 o

3 Static compression [Compression set(%)] 15 max 8 o

-6

๐

4 Coefficient of linear thermal expansion (1/ C) 150 x 10 max 92 x 10-6 o

5 Dimensional change due to heating (%) within ± 1.0 -0.1 o KANEKA (TH)

EPP 30XP

6 Tear strength (N/cm) Normal state 0.15 min 0.21 o Properties sheet

7 Tear strength (N/cm) After thermal resistance 0.15 min 0.2 o

8 Tear strength (N/cm) After humidity resistance 0.15 min 0.2 o

9 Tensile strength (MPa) Normal state 0.29 min 0.59 o

10 Tensile strength (MPa) After thermal resistance 0.29 min 0.57 o

11 Tensile strength (MPa) After humidity resistance 0.29 min 0.56 o

12 Flammability Test Original (mm/min) Refer STD 100 mm/min max nonflammable o KANEKA (TH)

13 Flammability Test After aging (mm/min) Refer STD 100 mm/min max 63 o LBK30R report

14 The Glass Fogging Test SGS TH Refer STD Method B : 90% (minimum) 98% o SGS No. 4188567

Intensity 3max 2.0 o

Dry condition Pleasantess -1.5 min -1.4 o

Smell Nature of smell Irritate / fishy : 1 max 0.0 / 0.0 o TUV SUD No.

15 TUV SUD Refer STD

Initial state Intensity 3max 0.6 o AM/R18/0207-0101

Wet condition Pleasantess -2.0 min -0.4 o

Nature of smell Irritate / fishy : 1 max 0.0 / 0.0 o

JUDGEMENT : O = OK , X = NG TF-MED-0001