Page 17 - 2021-2022 Commercial Drivers Manual

P. 17

SECTION 2 : DRIVING SAFETY

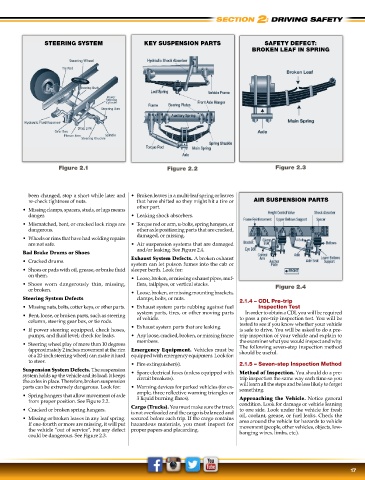

STEERING SYSTEM KEY SUSPENSION PARTS SAFETY DEFECT:

BROKEN LEAF IN SPRING

Figure 2.1 Figure 2.2 Figure 2.3

been changed, stop a short while later and • Broken leaves in a multi-leaf spring or leaves

re-check tightness of nuts. that have shifted so they might hit a tire or AIR SUSPENSION PARTS

other part.

• Missing clamps, spacers, studs, or lugs means

danger. • Leaking shock absorbers.

• Mismatched, bent, or cracked lock rings are • Torque rod or arm, u-bolts, spring hangers, or

dangerous. other axle positioning parts that are cracked,

damaged, or missing.

• Wheels or rims that have had welding repairs

are not safe. • Air suspension systems that are damaged

and/or leaking. See Figure 2.4.

Bad Brake Drums or Shoes

Exhaust System Defects. A broken exhaust

• Cracked drums.

system can let poison fumes into the cab or

• Shoes or pads with oil, grease, or brake fluid sleeper berth. Look for:

on them.

• Loose, broken, or missing exhaust pipes, muf-

• Shoes worn dangerously thin, missing, flers, tailpipes, or vertical stacks. Figure 2.4

or broken.

• Loose, broken, or missing mounting brackets,

Steering System Defects clamps, bolts, or nuts.

2.1.4 – CDL Pre-trip

• Missing nuts, bolts, cotter keys, or other parts. • Exhaust system parts rubbing against fuel Inspection Test

system parts, tires, or other moving parts In order to obtain a CDL you will be required

• Bent, loose, or broken parts, such as steering

column, steering gear box, or tie rods. of vehicle. to pass a pre-trip inspection test. You will be

• Exhaust system parts that are leaking. tested to see if you know whether your vehicle

• If power steering equipped, check hoses, is safe to drive. You will be asked to do a pre-

pumps, and fluid level; check for leaks. • Any loose, cracked, broken, or missing frame trip inspection of your vehicle and explain to

members. the examiner what you would inspect and why.

• Steering wheel play of more than 10 degrees

(approximately 2 inches movement at the rim Emergency Equipment. Vehicles must be The following seven-step inspection method

of a 20-inch steering wheel) can make it hard equipped with emergency equipment. Look for: should be useful.

to steer.

–

• Fire extinguisher(s). 2.1.5 Seven-step Inspection Method

Suspension System Defects. The suspension • Spare electrical fuses (unless equipped with Method of Inspection. You should do a pre-

system holds up the vehicle and its load. It keeps circuit breakers). trip inspection the same way each time so you

the axles in place. Therefore, broken suspension will learn all the steps and be less likely to forget

parts can be extremely dangerous. Look for: • Warning devices for parked vehicles (for ex- something.

ample, three reflective warning triangles or

• Spring hangers that allow movement of axle

from proper position. See Figure 2.2. 3 liquid burning flares). Approaching the Vehicle. Notice general

Cargo (Trucks). You must make sure the truck condition. Look for damage or vehicle leaning

• Cracked or broken spring hangers. to one side. Look under the vehicle for fresh

is not overloaded and the cargo is balanced and

• Missing or broken leaves in any leaf spring. secured before each trip. If the cargo contains oil, coolant, grease, or fuel leaks. Check the

If one-fourth or more are missing, it will put hazardous materials, you must inspect for area around the vehicle for hazards to vehicle

the vehicle “out of service”, but any defect proper papers and placarding. movement (people, other vehicles, objects, low-

could be dangerous. See Figure 2.3. hanging wires, limbs, etc.).

17