Page 48 - معین زیست آریا

P. 48

امرفراک

هناماس يزادنا هار و بصن ،تخاس ،هیهت ،یحارط

رتم رازه تسیب تیفرظ اب هتسب نک کنخ جرب

تعاس رد بعکم

DESIGN, PROCUREMENT,

CONSTRUCTION,

INSTALLATION AND

COMMISSIONING OF CLOSED

COOLING TOWER SYSTEM

WITH A COOLING WATER

CAPACITY OF 20,000 ⁄

CCT-20

DOCUMENT TITLE: REV:00 SHEET:

EQUIPMENT DOCUMENT NUMBER: Page 10 of 22

SPECIFICATION 60-06-DSH-ME-0002

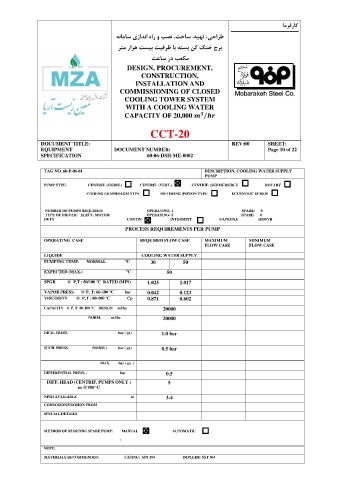

TAG NO. 60-P-06-01 DESCRIPTION. COOLING WATER SUPPLY

PUMP

PUMP TYPE: CENTRIF. (HORIZ.) CENTRIF. (VERT.) CENTRIF. (SUBMERSIBLE ROTARY

ETERING (DIAPHRAGM TYPE METERING (PISTON TYPE ECCENTRIC SCREW

NUMBER OF PUMPS REQUIRED: OPERATING: 1 SPARE: 0

TYPE OF DRIVER: ELECT. MOTOR: OPERATING: 1 SPARE: 0

DUTY CONTIN INTERMITT @APROXX HRS/YR

PROCESS REQUIREMENTS PER PUMP

OPERATING CASE REQUIRED FLOW CASE MAXIMUM MINIMUM

FLOW CASE FLOW CASE

LIQUIDE COOLING WATER SUPPLY

PUMPING TEMP. NORMAL o C 30 50

EXPECTED (MAX.) o C 50

SPGR @ P,T : 80/100 ºC RATED (MIN) 1.025 1.017

VAPOR PRESS. @ P, T: 60-100 ºC bar 0.042 0.123

VISCOSITY @ P,T : 80-100 ºC Cp 0.871 0.602

CAPACITY @ P, T: 80-100 ºC DESIGN m3/hr 20000

NORM. m3/hr 20000

DICH. PRESS. bar ( ga) 1.0 bar

SUCH. PRESS. (NORM.) bar ( ga) 0.5 bar

MAX. bar ( ga (

DIFFERENTIAL PRESS. : bar 0.5

DIFF. HEAD (CENTRIF. PUMPS ONLY ) 5

m @100 o C

NPSH AVAILABLE m 3-4

CORROSION/EROSION FROM

SPECIAL DETAILS

METHOD OF STARTING SPARE PUMP: MANUAL AUTOMATIC

:

NOTE.

MATERIALS RECOMMENDED: CASING: SST 304 IMPLLER: SST 304