Page 54 - SAEINDIA Magazine December 2020

P. 54

TECHNOLOGY

Trends

a b

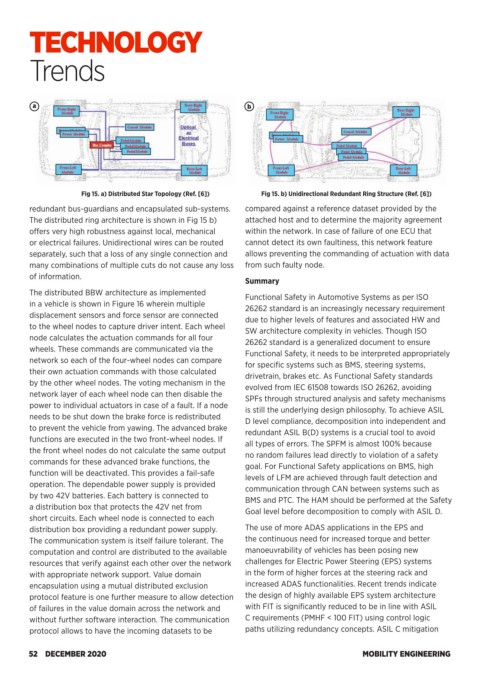

Fig 15. a) Distributed Star Topology (Ref. [6]) Fig 15. b) Unidirectional Redundant Ring Structure (Ref. [6])

redundant bus-guardians and encapsulated sub-systems. compared against a reference dataset provided by the

The distributed ring architecture is shown in Fig 15 b) attached host and to determine the majority agreement

offers very high robustness against local, mechanical within the network. In case of failure of one ECU that

or electrical failures. Unidirectional wires can be routed cannot detect its own faultiness, this network feature

separately, such that a loss of any single connection and allows preventing the commanding of actuation with data

many combinations of multiple cuts do not cause any loss from such faulty node.

of information.

Summary

The distributed BBW architecture as implemented Functional Safety in Automotive Systems as per ISO

in a vehicle is shown in Figure 16 wherein multiple 26262 standard is an increasingly necessary requirement

displacement sensors and force sensor are connected due to higher levels of features and associated HW and

to the wheel nodes to capture driver intent. Each wheel SW architecture complexity in vehicles. Though ISO

node calculates the actuation commands for all four 26262 standard is a generalized document to ensure

wheels. These commands are communicated via the Functional Safety, it needs to be interpreted appropriately

network so each of the four-wheel nodes can compare for specific systems such as BMS, steering systems,

their own actuation commands with those calculated drivetrain, brakes etc. As Functional Safety standards

by the other wheel nodes. The voting mechanism in the evolved from IEC 61508 towards ISO 26262, avoiding

network layer of each wheel node can then disable the SPFs through structured analysis and safety mechanisms

power to individual actuators in case of a fault. If a node is still the underlying design philosophy. To achieve ASIL

needs to be shut down the brake force is redistributed D level compliance, decomposition into independent and

to prevent the vehicle from yawing. The advanced brake redundant ASIL B(D) systems is a crucial tool to avoid

functions are executed in the two front-wheel nodes. If all types of errors. The SPFM is almost 100% because

the front wheel nodes do not calculate the same output no random failures lead directly to violation of a safety

commands for these advanced brake functions, the goal. For Functional Safety applications on BMS, high

function will be deactivated. This provides a fail-safe levels of LFM are achieved through fault detection and

operation. The dependable power supply is provided communication through CAN between systems such as

by two 42V batteries. Each battery is connected to BMS and PTC. The HAM should be performed at the Safety

a distribution box that protects the 42V net from Goal level before decomposition to comply with ASIL D.

short circuits. Each wheel node is connected to each

distribution box providing a redundant power supply. The use of more ADAS applications in the EPS and

The communication system is itself failure tolerant. The the continuous need for increased torque and better

computation and control are distributed to the available manoeuvrability of vehicles has been posing new

resources that verify against each other over the network challenges for Electric Power Steering (EPS) systems

with appropriate network support. Value domain in the form of higher forces at the steering rack and

encapsulation using a mutual distributed exclusion increased ADAS functionalities. Recent trends indicate

protocol feature is one further measure to allow detection the design of highly available EPS system architecture

of failures in the value domain across the network and with FIT is significantly reduced to be in line with ASIL

without further software interaction. The communication C requirements (PMHF < 100 FIT) using control logic

protocol allows to have the incoming datasets to be paths utilizing redundancy concepts. ASIL C mitigation

52 DECEMBER 2020 MOBILITY ENGINEERING