Page 58 - SAEINDIA Magazine December 2020

P. 58

LIGHTWEIGHT

Feature

HENKEL SHOWS HOW TO SLASH WEIGHT AND CUT

DEVELOPMENT TIME

German chemical major Henkel is eyeing smart gains with its strategic alliance

with RLE International. The company says it can help OEMs shed vehicle weight,

by a substantial 30kg in most cases while also increasing product strength

and bringing down product development time. Nilesh Wadhwa reports on the

lightweighting initiatives and their impact on the overall industry dynamics.

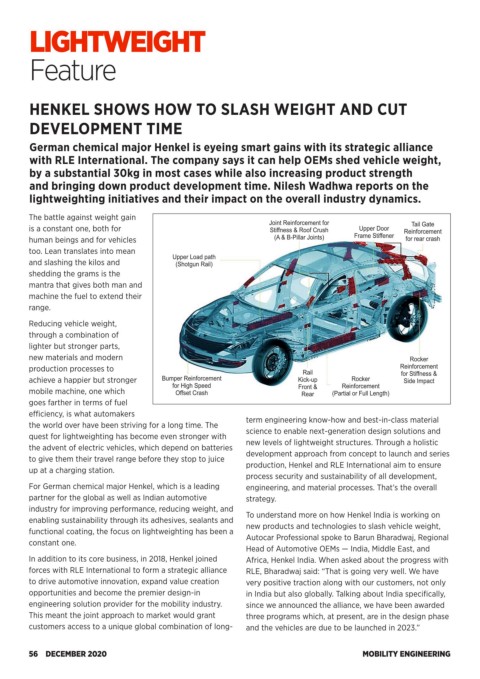

The battle against weight gain Joint Reinforcement for

Tail Gate

is a constant one, both for Stiffness & Roof Crush Upper Door Reinforcement

human beings and for vehicles (A & B-Pillar Joints) Frame Stiffener for rear crash

too. Lean translates into mean Upper Load path

and slashing the kilos and (Shotgun Rail)

shedding the grams is the

mantra that gives both man and

machine the fuel to extend their

range.

Reducing vehicle weight,

through a combination of

lighter but stronger parts,

new materials and modern Rocker

production processes to Rail Reinforcement

for Stiffness &

Rocker

achieve a happier but stronger Bumper Reinforcement Kick-up Reinforcement Side Impact

for High Speed

mobile machine, one which Offset Crash Front & (Partial or Full Length)

Rear

goes farther in terms of fuel

efficiency, is what automakers term engineering know-how and best-in-class material

the world over have been striving for a long time. The science to enable next-generation design solutions and

quest for lightweighting has become even stronger with new levels of lightweight structures. Through a holistic

the advent of electric vehicles, which depend on batteries development approach from concept to launch and series

to give them their travel range before they stop to juice production, Henkel and RLE International aim to ensure

up at a charging station.

process security and sustainability of all development,

For German chemical major Henkel, which is a leading engineering, and material processes. That’s the overall

partner for the global as well as Indian automotive strategy.

industry for improving performance, reducing weight, and To understand more on how Henkel India is working on

enabling sustainability through its adhesives, sealants and new products and technologies to slash vehicle weight,

functional coating, the focus on lightweighting has been a Autocar Professional spoke to Barun Bharadwaj, Regional

constant one.

Head of Automotive OEMs — India, Middle East, and

In addition to its core business, in 2018, Henkel joined Africa, Henkel India. When asked about the progress with

forces with RLE International to form a strategic alliance RLE, Bharadwaj said: “That is going very well. We have

to drive automotive innovation, expand value creation very positive traction along with our customers, not only

opportunities and become the premier design-in in India but also globally. Talking about India specifically,

engineering solution provider for the mobility industry. since we announced the alliance, we have been awarded

This meant the joint approach to market would grant three programs which, at present, are in the design phase

customers access to a unique global combination of long- and the vehicles are due to be launched in 2023.”

56 DECEMBER 2020 MOBILITY ENGINEERING