Page 63 - SAEINDIA Magazine December 2020

P. 63

LIGHTWEIGHT

Feature

Sandy Munro, CEO at Munro & Associates, the

benchmarking and competitive analysis firm renowned

for its highly analytic “teardowns” of popular and

innovative vehicles, recently completed a teardown of

a Model Y. A series of internet videos covering Munro’s

assessment garnered more than 36 million impressions

in little more than a month. Munro was particularly

impressed by the current two-piece aluminum underbody

structure – and openly offered admiration in an interview

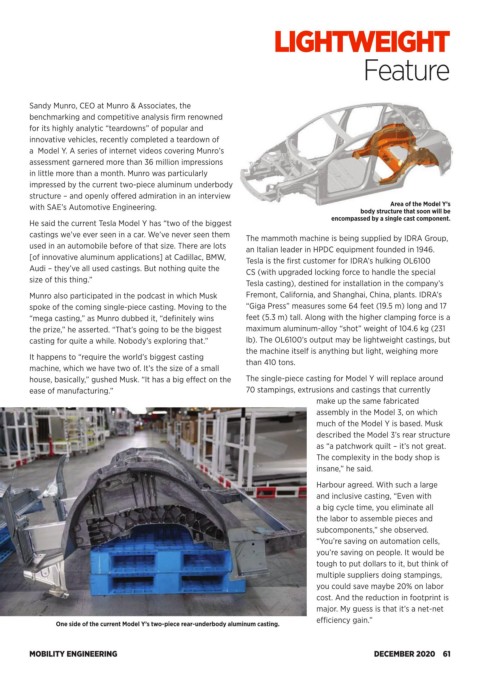

Area of the Model Y’s

with SAE’s Automotive Engineering. body structure that soon will be

encompassed by a single cast component.

He said the current Tesla Model Y has “two of the biggest

castings we’ve ever seen in a car. We’ve never seen them The mammoth machine is being supplied by IDRA Group,

used in an automobile before of that size. There are lots an Italian leader in HPDC equipment founded in 1946.

[of innovative aluminum applications] at Cadillac, BMW, Tesla is the first customer for IDRA’s hulking OL6100

Audi – they’ve all used castings. But nothing quite the CS (with upgraded locking force to handle the special

size of this thing.” Tesla casting), destined for installation in the company’s

Munro also participated in the podcast in which Musk Fremont, California, and Shanghai, China, plants. IDRA’s

spoke of the coming single-piece casting. Moving to the “Giga Press” measures some 64 feet (19.5 m) long and 17

“mega casting,” as Munro dubbed it, “definitely wins feet (5.3 m) tall. Along with the higher clamping force is a

the prize,” he asserted. “That’s going to be the biggest maximum aluminum-alloy “shot” weight of 104.6 kg (231

casting for quite a while. Nobody’s exploring that.” lb). The OL6100’s output may be lightweight castings, but

the machine itself is anything but light, weighing more

It happens to “require the world’s biggest casting than 410 tons.

machine, which we have two of. It’s the size of a small

house, basically,” gushed Musk. “It has a big effect on the The single-piece casting for Model Y will replace around

ease of manufacturing.” 70 stampings, extrusions and castings that currently

make up the same fabricated

assembly in the Model 3, on which

much of the Model Y is based. Musk

described the Model 3’s rear structure

as “a patchwork quilt – it’s not great.

The complexity in the body shop is

insane,” he said.

Harbour agreed. With such a large

and inclusive casting, “Even with

a big cycle time, you eliminate all

the labor to assemble pieces and

subcomponents,” she observed.

“You’re saving on automation cells,

you’re saving on people. It would be

tough to put dollars to it, but think of

multiple suppliers doing stampings,

you could save maybe 20% on labor

cost. And the reduction in footprint is

major. My guess is that it’s a net-net

efficiency gain.”

One side of the current Model Y’s two-piece rear-underbody aluminum casting.

MOBILITY ENGINEERING DECEMBER 2020 61