Page 193 - eProceeding - IRSTC & RESPEX 2017

P. 193

Shaifatulna’im Binti Shamsuddin / JOJAPS – JOURNAL ONLINE JARINGAN COT POLIPD

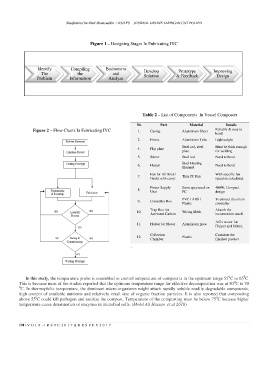

Figure 1 – Designing Stages In Fabricating IVC

Identify Compiling Brainstorm Develop Prototype Improving

The the and

Problem Information Analyze Solution & Feedback Design

Table 2 – List of Components In Vessel Composter

No Part Material Details

Figure 2 – Flow Charts In Fabricating IVC 1. Casing Aluminium Sheet Reliable & easy to

bend

2. Frame Aluminium Tube Lightweight

Steel rod, steel Must be thick enough

4. Flip plate

plate for welding

5. Stirrer Steel rod Need to bend

Steel Heating

6. Heater Need to bend

Element

Fan for Air Inlet / With specific fan

7. Thin PC Fan

Outlet with cover speed as calculated.

Power Supply Same spec used on 400W, Compact

8.

Unit PC design

PVC / ABS / To protect the micro

9. Controller Box

Plastic controller

Trap Box for Absorb the

10. Wiring Mesh

Activated Carbon inconvenient smell.

Affix motor for

11. Holder for Motor Aluminium plate

Flipper and Stirrer,

Collection Container for

12. Plastic

Chamber finished product

.

0

0

In this study, the temperature probe is assembled to control temperature of compost is in the optimum range 55 C to 65 C .

0

This is because most of the studies reported that the optimum temperature range for effective decomposition was at 50 C to 70

0

C. In thermophilic temperature, the dominant micro-organisms might attack rapidly soluble readily degradable compounds,

high content of available nutrients and relatively small size of organic fraction particles. It is also reported that composting

0

0

above 55 C could kill pathogen and sanitize the compost. Temperature of the composting must be below 75 C because higher

temperature cause denaturation of enzymes in microbial cells. (Mohd Ali Hassan et al 2010)

191 | V O L 8 - I R S T C 2 0 1 7 & R E S P E X 2 0 1 7