Page 6 - BREDI-CW

P. 6

BREDI offers a comprehensive range of thermally broken windows,door and facade known as ®

BREDI-S , BREDI-H and BREDI-F These systems designed and tested to maximize thermal ® ® ®

performance and meet contemporary aspirations for energy efficiency. BREDI residential window ®

and door systems deliver up to 33% better efficiency than comparable double glazed aluminium

system.

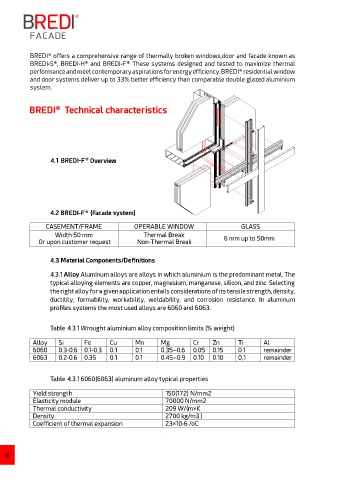

4.1 BREDI-F® Overview

4.2 BREDI-F® (Facade system)

CASEMENT/FRAME OPERABLE WINDOW GLASS

Width 50 mm Thermal Break

Or upon customer request Non-Thermal Break 6 mm up to 50mm

4.3 Material Components/Denitions

4.3.1 Alloy Aluminum alloys are alloys in which aluminium is the predominant metal. The

typical alloying elements are copper, magnesium, manganese, silicon, and zinc. Selecting

the right alloy for a given application entails considerations of its tensile strength, density,

ductility, formability, workability, weldability, and corrosion resistance. In aluminum

proles systems the most used alloys are 6060 and 6063.

Table 4.3.1 Wrought aluminium alloy composition limits (% weight)

Alloy Si Fe Cu Mn Mg Cr Zn Ti Al

6060 0.3-0.6 0.1-0.3 0.1 0.1 0.35–0.6 0.05 0.15 0.1 remainder

6063 0.2-0.6 0.35 0.1 0.1 0.45–0.9 0.10 0.10 0,1 remainder

Table 4.3.1 6060(6063) aluminum alloy typical properties

Yield strength 150(172) N/mm2

Elasticity module 70000 N/mm2

Thermal conductivity 209 W/(m×K

Density 2700 kg/m3 )

Coefficient of thermal expansion 23×10-6 /oC

4