Page 114 - 00. Complete Version - Progress Report IPEN 2014-2016

P. 114

114 Renewable Energies | Progress Report

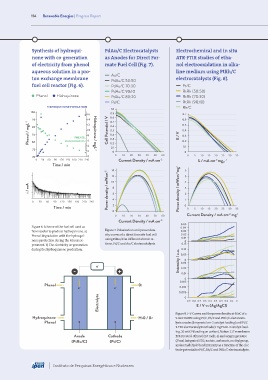

Synthesis of hydroqui- PdAu/C Electrocatalysts Electrochemical and in situ

none with co-generation as Anodes for Direct For- ATR-FTIR studies of etha-

of electricity from phenol mate Fuel Cell (Fig. 7). nol electrooxidation in alka-

aqueous solution in a pro- line medium using PtRh/C

Au/C

ton exchange membrane PdAu/C 50:50 electrocatalysts (Fig. 8).

fuel cell reactor (Fig. 6). PdAu/C 70:30 Pt/C

PdAu/C 90:10 RtRh (50:50)

Phenol Hidroquinone PdAu/C 80:20 RtRh (70:30)

Pd/C RtRh (90:10)

HIDROQUINONE FORMATION Rh/C

1.0

100

16 0.9 0.7

95 14 0.8 0.6

0.7

Phenol / mgL -1 90 PHENOL 10 Hidroquinone / mgL -1 Cell Potential / V 0.5 E / V 0.4

0.5

12

0.6

85

0.4

8

0.3

0.3

DEGRADATION

80

4 6 0.2 0.2

0.1

75 2 0.1 0 0

70 0 0 10 20 30 40 50 60 0 5 10 15 20 25 30 35

-2

0 30 60 90 120 150 160 210 240 Current Density / mA cm -2 L / mA cm mg pt -1

Time / min

14 6 5

Power density / mWcm -2 6 2

12

i / mA 10 8 Power density / mWcm -2 mg 1 4 3

0 30 60 90 120 150 160 210 240 4 1

Time / min 2 0 0 5 10 15 20 25 30 35

0

-2

0 10 20 30 40 50 60 Current Density / mA cm mg -1

Current Density / mA cm -2

0.05

Figure 6. Scheme of the fuel cell used as 0.04

flow reactor to produce hydroquinone. a) Figure 7. Polarization and power den- 0.03

Phenol degradation with the hydroqui- sity curves of a direct formate fuel cell 0.02

0.01

none production during the 4 hour ex- using PdAu/C in different atomic ra- 0

periment. b) The electricity co-generation tions, Pd/C and Au/C electrocatalysts. 0.15

0.10

during the hydroquinone production. 0.05

Intensity / a.u. 0.03 0

e - 0.02

0.01

0

0.015

Phenol 02

e - e - 0.010

0.005 0

Electrolyte -0.9 -0.8 -0.7 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1 0

E / V vs (Ag/AgCl)

Figure 8. I–V Curves and the power density at 60oC of a

Hydroquinone H20 / 02 5 cm2 DAEFC using Pt/C, Rh/C and PtRh/C electrocata-

Phenol lysts anodes (1mgmetal cm-2 catalyst loading) and Pt/C

E-TEK electrocatalyst cathode(1 mgPt cm-2 catalyst load-

ing, 20 wt% Pt loading on carbon), Nafion 117 membrane

Anode Cathode KOH treated, ethanol (2.0 mol L-1) and oxygen pressure

(PtRu/C) (Pt/C) (2 bar). Integrated CO2, acetate, carbonate, methyl group,

andacetaldehyde band intensity as a function of the elec-

trode potentialfor Pt/C, Rh/C and PtRh/C electrocatalysts.

Instituto de Pesquisas Energéticas e Nucleares