Page 11 - The HandPrint_November-December

P. 11

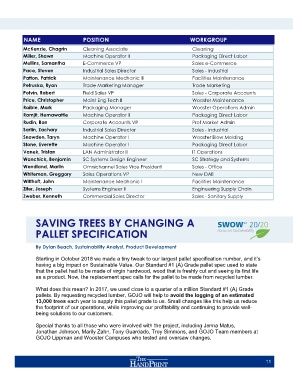

NAME POSITION WORKGROUP

McKenzie, Chagrin Cleaning Associate Cleaning

Miller, Shawn Machine Operator II Packaging Direct Labor

Mullins, Samantha E-Commerce VP Sales e-Commerce

Pace, Steven Industrial Sales Director Sales - Industrial

Patton, Patrick Maintenance Mechanic III Facilities Maintenance

Petruska, Ryan Trade Marketing Manager Trade Marketing

Potvin, Robert Field Sales VP Sales - Corporate Accounts

Price, Christopher Maint Eng Tech II Wooster Maintenance

Raible, Mark Packaging Manager Wooster Operations Admin

Ramjit, Hemawattie Machine Operator II Packaging Direct Labor

Rudin, Ron Corporate Accounts VP Prof Market Admin

Sartin, Zachary Industrial Sales Director Sales - Industrial

Snowden, Taryn Machine Operator I Wooster Blow Molding

Stone, Everette Machine Operator I Packaging Direct Labor

Vanek, Tristan LAN Administrator II IT Operations

Wanchick, Benjamin SC Systems Design Engineer SC Strategy and Systems

Wendland, Marlin Omnichannel Sales Vice President Sales - Office

Whiteman, Greggory Sales Operations VP New DAE

Witthoft, John Maintenance Mechanic I Facilities Maintenance

Zifer, Joseph Systems Engineer II Engineering Supply Chain

Zweber, Kenneth Commercial Sales Director Sales - Sanitary Supply

SAVING TREES BY CHANGING A

PALLET SPECIFICATION

By Dylan Beach, Sustainability Analyst, Product Development

Starting in October 2018 we made a tiny tweak to our largest pallet specification number, and it’s

having a big impact on Sustainable Value. Our Standard #1 (A) Grade pallet spec used to state

that the pallet had to be made of virgin hardwood, wood that is freshly cut and seeing its first life

as a product. Now, the replacement spec calls for the pallet to be made from recycled lumber.

What does this mean? In 2017, we used close to a quarter of a million Standard #1 (A) Grade

pallets. By requesting recycled lumber, GOJO will help to avoid the logging of an estimated

13,000 trees each year to supply this pallet grade to us. Small changes like this help us reduce

the footprint of our operations, while improving our profitability and continuing to provide well-

being solutions to our customers.

Special thanks to all those who were involved with the project, including Jenna Matus,

Jonathan Johnson, Marily Zahn, Tony Guardado, Troy Simmons, and GOJO Team members at

GOJO Lippman and Wooster Campuses who tested and oversaw changes.

11