Page 100 - UL_Report On_Part 1

P. 100

91 IITGN-UL/Façade 92 IITGN-UL/Façade

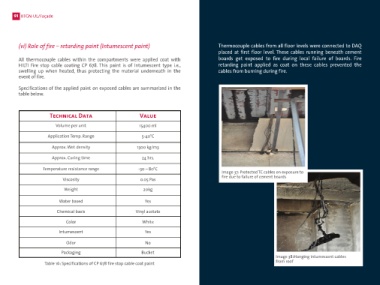

(vi) Role of fire – retarding paint (Intumescent paint) Thermocouple cables from all floor levels were connected to DAQ

placed at first floor level. These cables running beneath cement (vi) Behavior of fire doors and vision panels

All thermocouple cables within the compartments were applied coat with boards get exposed to fire during local failure of boards. Fire

HILTI Fire stop cable coating CP 678. This paint is of Intumescent type i.e., retarding paint applied as coat on these cables prevented the

swelling up when heated, thus protecting the material underneath in the cables from burning during fire. UL listed fire door remained intact during all fire

event of fire. tests. It could withstand close to 45 min of intense

heat. The unexposed side of the door was found to

Specifications of the applied paint on exposed cables are summarized in the be in good condition and the paint and system

table below. integrity of fire door was found to be in perfect

condition. Vision panel of fire door was broken due

to impact of water jet during firefighting

Technical Data Value operations.

Volume per unit 15400 ml

Application Temp. Range 5-40°C

Approx. Wet density 1300 kg/m3

Approx. Curing time 24 hrs.

Temperature resistance range -30 – 80°C

Image 37: Protected TC cables on exposure to

fire due to failure of cement boards

Viscosity 0.05 Pas

Weight 20kg

Water based Yes

Chemical basis Vinyl acetate

Color White Image 40: Unexposed side of fire door

Intumescent Yes

Odor No

Packaging Bucket

Image 38:Hanging intumescent cables Image 41: Broken vision panel of fire door

Table 16: Specifications of CP 678 fire stop cable coat paint from roof Image 39: Exposed side of fire door due to impact of water jet