Page 7 - BlueFastening-Systems_Brochure_07192017

P. 7

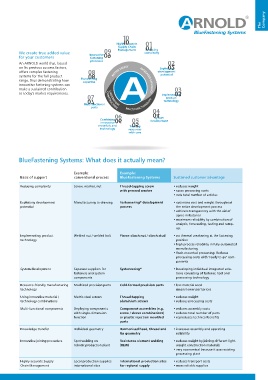

We create true added value BETHighly accurate Reducing

for your customers LITYSupply Chaincomplexity

An ARNOLD world that, based Management

on its previous success factors, The

offers complex fastening Innovative CompanyTER SAFETYINCRExploiting

systems for the full product fastening development

range, thus demonstrating how processes EASED EFFICIENCY

innovative fastening systems can Transferring LCIGOHNTSWTREUIGCT potential

make a sustained contribution expertise

to today's market requirements.

Implementing

IONHT MULTI-FUNCTIONA product

technology

Multifunctional

parts

Combining System

innovative development

materials and

technology Treating

resources

with care

BlueFastening Systems: What does it actually mean?

Basis of support Example: Example: Sustained customer advantage

Reducing complexity conventional process BlueFastening Systems

Screw, washer, nut Thread-tapping screw • reduces weight

Exploiting development with pressed washer • saves processing costs

potential Manufacturing to drawing • cuts total number of articles

Fasteneering® development

Implementing product Welded nut / welded bolt process • optimises cost and weight throughout

technology the entire development process

Pierce-clinch nut / clinch stud

System development Separate suppliers for • achieves transparency with the aid of

fasteners and system Systeneering® agree milestones

Resource-friendly manufacturing components

technology Cold-formed precision parts • maximum reliability by combination of

Using innovative material / Machined precision parts analysis, forecasting, testing and ramp-

technology combinations Thread-tapping up.

Multi-functional components Metric steel screws aluminium screws

Component assemblies (e.g. • no thermal weakening at the fastening

Deploying components screw / sleeve combinations) position

with single-dimension or plastic injection moulded

function parts • high process reliability in fully-automated

Harmonised head, thread and manufacturing

tip geometry

Resistance element welding • flush-mounted processing. Reduces

(REW) processing costs with "ready to go" com-

ponents

International production sites

for regional supply • Developing individual integrated solu-

tions consisting of fastener, tool and

processing technology

• less material used

means lower part prices

• reduces weight

• reduces processing costs

• reduces assembly costs

• reduces total number of parts

• reproduces technical benefits

Knowledge transfer Individual geometry • increases assembly and operating

reliability

Innovative joining procedure Spot welding on • reduces weight by joining different light-

robotic production plant weight construction materials

• very economical because it uses existing

processing plant

Highly accurate Supply Local production supplies • reduces transport costs 07

Chain Management international sites • more reliable supplies