Page 76 - BlueFastening-Systems_Brochure_07192017

P. 76

Especially suitable for use in thin sheet-metals

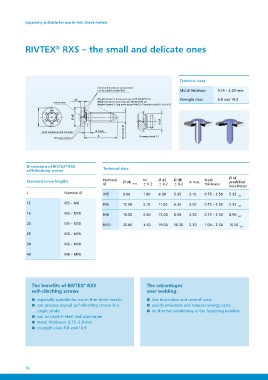

RIVTEX® RXS – the small and delicate ones

Indentation hK Contour depends on manufacture Technical data 0.75 – 2.00 mm

can be slightly underfilled Metal thickness 8.8 and 10.9

Weight Variant 1: Cone point as per EN ISO 4753 CH Strength class

Weight Variant 2: Journal as per EN ISO 4753 LD

Weight Variant 3: Dog point as per WN-23-7 (similar to EN ISO 4753-PC)

Ø dK

Nominal Ø

Ø dR

Head marking A and strength Z Drawing detail 3:1

Pressing contour

A max.

L

Dimensions of RIVTEX® RXS Technical data

self-clinching screws

Standard screw lengths Nominal Ø dK -0.43 hK Ø dS Ø dR A max. Steel Ø of

L Nominal Ø Ø 9.00 ± 0.2 ± 0.2 ± 0.2 thickness predrilled

12 M5 – M6 M5 1.80 8.30 5.35 hole Metal

16 M5 – M10 3.10 0.75 – 2.50 5.35 -0.1

20 M5 – M10

25 M5 – M10 M6 12.00 2.10 11.00 6.35 3.50 0.75 – 2.50 5.35 -0.1

30 M6 – M10

40 M8 – M10 M8 16.00 2.80 15.00 8.50 4.50 0.75 – 2.50 8.50 -0.1

M10 20.00 3.50 19.00 10.50 5.30 1.00 – 2.50 10.50 -0.1

The benefits of RIVTEX® RXS The advantages

self-clinching screws over welding:

especially suitable for use in thin sheet-metals low inspection and control costs

can process several self-clinching screws in a avoids emissions and reduces energy costs

single stroke no thermal weakening at the fastening position

can be used in steel and aluminium

metal thickness: 0.75 -2.0 mm

strength class 8.8 and 10.9

02 76