Page 232 - Copper and Bronze in Art: Corrosion, Colorants, Getty Museum Conservation, By David Scott

P. 232

78

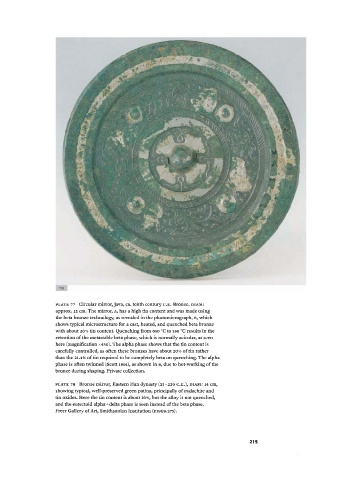

P L A T E 77 Circular mirror, Java, ca. tenth century C . E . Bronze, D I A M :

A

approx. 12 cm. The mirror, , has a high tin content and was made using

B

the beta bronze technology, as revealed in the photomicrograph, , which

shows typical microstructure for a cast, heated, and quenched beta bronze

with about 20% tin content. Quenching from 5 0 °C to 550 °C results in the

6

retention of the metastable beta phase, which is normally acicular, as seen

here (magnification χ43θ). The alpha phase shows that the tin content is

carefully controlled, as often these bronzes have about 20% of tin rather

than the 21.4% of tin required to be completely beta on quenching. The alpha

B

phase is often twinned (Scott 1991), as shown in , due to hot-working of the

bronze during shaping. Private collection.

P L A T E 7 8 Bronze mirror, Eastern Han dynasty (25-22 0 C . E . ) , D I A M : 14 cm,

showing typical, well-preserved green patina, principally of malachite and

tin oxides. Here the tin content is about 19%, but the alloy is not quenched,

and the eutectoid alpha+delta phase is seen instead of the beta phase.

Freer Gallery of Art, Smithsonian Institution (F1909.275).

215