Page 7 - Revised Catalog

P. 7

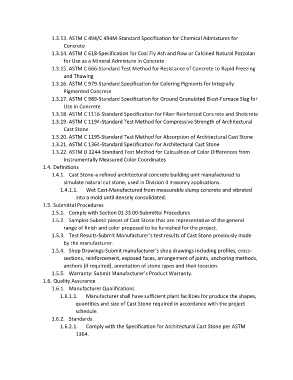

1.3.13. ASTM C 494/C 494M-Standard Specification for Chemical Admixtures for

Concrete

1.3.14. ASTM C 618-Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan

for Use as a Mineral Admixture in Concrete

1.3.15. ASTM C 666-Standard Test Method for Resistance of Concrete to Rapid Freezing

and Thawing

1.3.16. ASTM C 979-Standard Specification for Coloring Pigments for Integrally

Pigmented Concrete

1.3.17. ASTM C 989-Standard Specification for Ground Granulated Blast-Furnace Slag for

Use in Concrete

1.3.18. ASTM C 1116-Standard Specification for Fiber Reinforced Concrete and Shotcrete

1.3.19. ASTM C 1194-Standard Test Method for Compressive Strength of Architectural

Cast Stone

1.3.20. ASTM C 1195-Standard Test Method for Absorption of Architectural Cast Stone

1.3.21. ASTM C 1364-Standard Specification for Architectural Cast Stone

1.3.22. ASTM D 2244-Standard Test Method for Calcualtion of Color Differences from

Instrumentally Measured Color Coordinates

1.4. Definitions

1.4.1. Cast Stone-a refined architectural concrete building unit manufactured to

simulate natural cut stone, used in Division 4 masonry applications.

1.4.1.1. Wet Cast-Manufactured from measurable slump concrete and vibrated

into a mold until densely consolidated.

1.5. Submittal Procedures

1.5.1. Comply with Section 01 33 00-Submittal Procedures

1.5.2. Samples-Submit pieces of Cast Stone that are representative of the general

range of finish and color proposed to be furnished for the project.

1.5.3. Test Results-Submit Manufacturer’s test results of Cast Stone previously made

by the manufacturer.

1.5.4. Shop Drawings-Submit manufacturer’s shop drawings including profiles, cross-

sections, reinforcement, exposed faces, arrangement of joints, anchoring methods,

anchors (if required), annotation of stone types and their location.

1.5.5. Warranty: Submit Manufacturer’s Product Warranty.

1.6. Quality Assurance

1.6.1. Manufacturer Qualifications

1.6.1.1. Manufacturer shall have sufficient plant facilities for produce the shapes,

quantities and size of Cast Stone required in accordance with the project

schedule.

1.6.2. Standards

1.6.2.1. Comply with the Specification for Architectural Cast Stone per ASTM

1364.