Page 77 - 2018 Racecar Engineering Engine Parts and Accessories Catalog

P. 77

PISTON RINGS

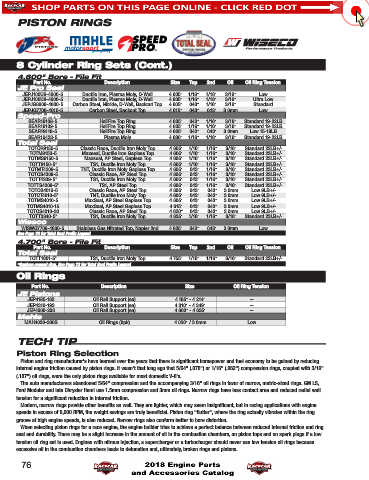

8 Cylinder Ring Sets (Cont.)

4.600" Bore - File Fit

Part No. Description Size Top 2nd Oil Oil Ring Tension

JE Pro Seal

JEPJ100U8-4600-5 Ductile Iron, Plasma Moly, D-Wall 4.605" 1/16" 1/16" 3/16" Low

JEPJ100U8-4600-5 Ductile Iron, Plasma Moly, D-Wall 4.605" 1/16" 1/16" 3/16" Ultra Low

JEPJG8608-4600-5 Carbon Steel, Nitride, D-Wall, Backcut Top 4.605" .043" 1/16" 3/16" Standard

JEPJG7708-4610-5 Carbon Steel, Backcut Top 4.615" .043" .043" 3.0mm Low

Speed-Pro

SEAR19108-5 HellFire Top Ring 4.605" .043" 1/16" 3/16" Standard 19-22LB

SEAR19109-5 HellFire Top Ring 4.605" 1/16" 1/16" 3/16" Standard 19-22LB

SEAR19118-5 HellFire Top Ring 4.605" .043" .043" 3.0mm Low 15-18LB

SEAR10433-5 Plasma Moly 4.630" 1/16" 1/16" 3/16" Standard 19-22LB

Total Seal

TOTCR9150-5 Classic Race, Ductile Iron Moly Top 4.605" 1/16" 1/16" 3/16" Standard 23LB+/-

TOTM9150-5 Maxseal, Ductile Iron Gapless Top 4.605" 1/16" 1/16" 3/16" Standard 23LB+/-

TOTMS9150-5 Maxseal, AP Steel, Gapless Top 4.605" 1/16" 1/16" 3/16" Standard 23LB+/-

TOTT9150-5* TS1, Ductile Iron Moly Top 4.605" 1/16" 1/16" 3/16" Standard 23LB+/-

TOTMT4309-5 TNT, Ductile Iron Moly Gapless Top 4.605" .043" 1/16" 3/16" Standard 23LB+/-

TOTCS4309-5 Classic Race, AP Steel Top 4.605" .043" 1/16" 3/16" Standard 23LB+/-

TOTT4309-5* TS1, Ductile Iron Moly Top 4.605" .043" 1/16" 3/16" Standard 23LB+/-

TOTTS4309-5* TS1, AP Steel Top 4.605" .043" 1/16" 3/16" Standard 23LB+/-

TOTCS4010-5 Classic Race, AP Steel Top 4.605" .043" .043" 3.0mm Low 9LB+/-

TOTCT4010-5* TNT, Ductile Iron Moly Top 4.605" .043" .043" 3.0mm Low 9LB+/-

TOTMS4010-5 MaxSeal, AP Steel Gapless Top 4.605" .043" .043" 3.0mm Low 9LB+/-

TOTMS4010-15 MaxSeal, AP Steel Gapless Top 4.615" .043" .043" 3.0mm Low 9LB+/-

TOTCS4010-30 Classic Race, AP Steel Top 4.630" .043" .043" 3.0mm Low 9LB+/-

TOTT3340-5* TS1, Ductile Iron Moly Top 4.635" 1/16" 1/16" 3/16" Standard 23LB+/-

Wiseco

WISWG7708-4600-5 Stainless Gas Nitrated Top, Napier 2nd 4.605" .043" .043" 3.0mm Low

See Page 73 for Total Seal Prefix Legend

4.700" Bore - File Fit

Part No. Description Size Top 2nd Oil Oil Ring Tension

Total Seal

TOTT1601-5* TS1, Ductile Iron Moly Top 4.755" 1/16" 1/16" 3/16" Standard 23LB+/-

*Gapless second ring. See Page 73 for Total Seal Prefix Legend

Oil Rings

Part No. Description Size Oil Ring Tension

JE Pistons

JEP4185-183 Oil Rail Support (ea) 4.185" - 4.214" —

JEP4310-193 Oil Rail Support (ea) 4.310" - 4.349" —

JEP4600-203 Oil Rail Support (ea) 4.600" - 4.635" —

Mahle

MAH4030-300S Oil Rings (8pk) 4.030" / 3.0mm Low

TECH TIP

Piston Ring Selection

Piston and ring manufacturer's have learned over the years that there is significant horsepower and fuel economy to be gained by reducing

internal engine friction caused by piston rings. It wasn't that long ago that 5/64" (.078") or 1/16" (.062") compression rings, coupled with 3/16"

(.187") oil rings, were the only piston rings available for most domestic V-8's.

The auto manufacturers abandoned 5/64" compression and the accompanying 3/16" oil rings in favor of narrow, metric-sized rings. GM LS,

Ford Modular and late Chrysler Hemi use 1.5mm compression and 3mm oil rings. Narrow rings have less contact area and reduced radial wall

tension for a significant reduction in internal friction.

Modern, narrow rings provide other benefits as well. They are lighter, which may seem insignificant, but in racing applications with engine

speeds in excess of 8,000 RPM, the weight savings are truly beneficial. Piston ring "flutter", where the ring actually vibrates within the ring

groove at high engine speeds, is also reduced. Narrow rings also conform better to bore distortion.

When selecting piston rings for a race engine, the engine builder tries to achieve a perfect balance between reduced internal friction and ring

seal and durability. There may be a slight increase in the amount of oil in the combustion chambers, on piston tops and on spark plugs if a low

tension oil ring set is used. Engines with nitrous injection, a supercharger or a turbocharger should never use low tension oil rings because

excessive oil in the combustion chambers leads to detonation and, ultimately, broken rings and pistons.

76 2018 ENGINE BUILDER CATALOG