Page 14 - Introduction

P. 14

Don’t leave it to chance, get it right first time, if you think it’s expensive to hire a

professional wait to you count the costs of hiring a amateur.

Contact us on Skype/Phone: +44 (0) 161 8188974, Mobile: +44 (0) 7488298027,

email: paul.mcmullan@subtechengineers.com

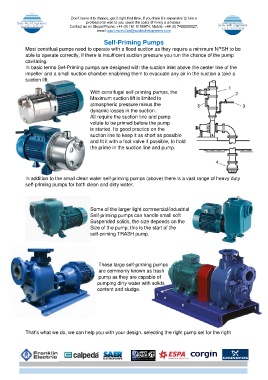

Self-Priming Pumps

Most centrifual pumps need to operate with a flood suction as they require a minimum NPSH to be

able to operate correctly, if there is insufficent suction pressure you run the chance of the pump

cavitating.

In basic terms Sef-Priming pumps are designed with the suction inlet above the center line of the

impeller and a small suction chamber enableing them to evacuate any air in the suction a take a

suction lift.

With centrifugal self-priming pumps, the

Maximum suction lift is limited to

atmospheric pressure minus the

dynamic losses in the suction.

All require the suction line and pump

volute to be primed before the pump

is started. Its good practice on the

suction line to keep it as short as possible

and fit it with a foot valve if possible, to hold

the prime in the suction line and pump.

In addition to the small clean water self-priming pumps (above) there is a vast range of heavy duty

self-priming pumps for both clean and dirty water.

Some of the larger light commercial/industrial

Self-priming pumps can handle small soft

Suspended solids, the size depends on the

Size of the pump, this is the start of the

self-priming TRASH pump.

These large self-priming pumps

are commonly known as trash

pump as they are capable of

pumping dirty water with solids

content and sludge.

That’s what we do, we can help you with your design, selecting the right pump set for the right