Page 13 - Feed Lab

P. 13

Suguna Management System Ver 1.0 / RR / FQL / 03 Page 1 of 2

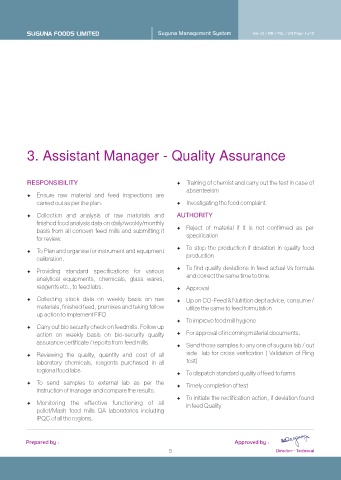

3. Assistant Manager - Quality Assurance

FTraining of chemist and carry out the test in case of

RESPONSIBILITY

absenteeism

FEnsure raw material and feed inspections are

carried out as per the plan. FInvestigating the feed complaint.

FCollection and analysis of raw materials and AUTHORITY

finished feed analysis data on daily/weekly/monthly

basis from all concern feed mills and submitting it FReject of material if it is not confirmed as per

for review. specification

FTo stop the production if deviation in quality feed

FTo Plan and organise for instrument and equipment

calibration. production

FTo find quality deviations in feed actual Vs formula

FProviding standard specifications for various

analytical equipments, chemicals, glass wares, and correct the same time to time.

reagents etc., to feed labs. FApproval

FCollecting stock data on weekly basis on raw FUp on CO-Feed & Nutrition dept advice, consume /

materials, finished feed, premixes and taking follow utilize the same to feed formulation

up action to implement FIFO

FTo improve feed mill hygiene

FCarry out bio security check on feedmills. Follow up

action on weekly basis on bio-security quality FFor approval of incoming material documents.

assurance certificate / reports from feed mills.

FSend those samples to any one of suguna lab / out

FReviewing the quality, quantity and cost of all side lab for cross verification ( Validation of Ring

laboratory chemicals, reagents purchased in all test)

regional feed labs

FTo dispatch standard quality of feed to farms

FTo send samples to external lab as per the FTimely completion of test

instruction of manager and compare the results.

FTo initiate the rectification action, if deviation found

FMonitoring the effective functioning of all in feed Quality

pellet/Mash feed mills QA laboratories including

IPQC of all the regions.

Prepared by : Approved by :

5 Director - Technical