Page 50 - Inbound Logistics | April 2017 | Digital Issue

P. 50

SPONSORED CONTENT

Supply Chain Challenge?

SOLVED!

Auditing Beyond Compliance

Evaluating the continuing alignment of customer requirements, acceptable associated

risk and service provider capability.

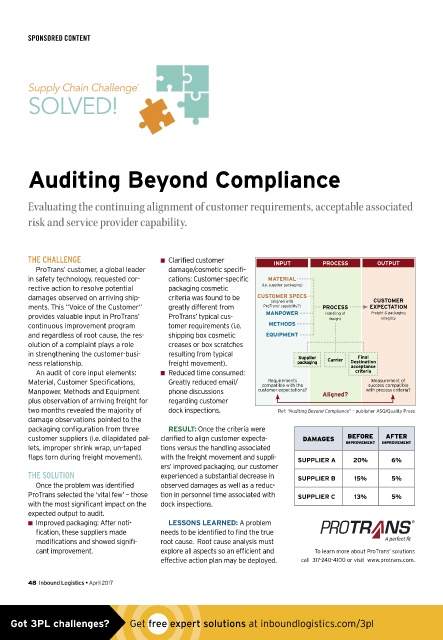

THE CHALLENGE n ■ Clarified customer INPUT PROCESS OUTPUT

ProTrans’ customer, a global leader damage/cosmetic specifi-

in safety technology, requested cor- cations: Customer-specific MATERIAL

rective action to resolve potential packaging cosmetic (i.e. supplier packaging)

damages observed on arriving ship- criteria was found to be CUSTOMER SPECS

(aligned with CUSTOMER

ments. This “Voice of the Customer” greatly different from ProTrans’ capability?) PROCESS EXPECTATION

provides valuable input in ProTrans’ ProTrans’ typical cus- MANPOWER Handling of Freight & packaging

integrity

freight

continuous improvement program tomer requirements (i.e. METHODS

and regardless of root cause, the res- shipping box cosmetic EQUIPMENT

olution of a complaint plays a role creases or box scratches

in strengthening the customer-busi- resulting from typical Supplier Final

ness relationship. freight movement). packaging Carrier Destination

acceptance

An audit of core input elements: n ■ Reduced time consumed: criteria

Requirements

Measurement of

Material, Customer Specifications, Greatly reduced email/ compatible with the success compatible

Manpower, Methods and Equipment phone discussions customer expectations? Aligned? with process criteria?

plus observation of arriving freight for regarding customer

two months revealed the majority of dock inspections. Ref: “Auditing Beyond Compliance” – publisher ASQ/Quality Press

damage observations pointed to the

packaging configuration from three RESULT: Once the criteria were

customer suppliers (i.e. dilapidated pal- clarified to align customer expecta- DAMAGES BEFORE AFTER

IMPROVEMENT IMPROVEMENT

lets, improper shrink wrap, un-taped tions versus the handling associated

flaps torn during freight movement). with the freight movement and suppli- SUPPLIER A 20% 6%

ers’ improved packaging, our customer

THE SOLUTION experienced a substantial decrease in SUPPLIER B 15% 5%

Once the problem was identified observed damages as well as a reduc-

ProTrans selected the ‘vital few’ – those tion in personnel time associated with SUPPLIER C 13% 5%

with the most significant impact on the dock inspections.

expected output to audit.

n ■ Improved packaging: After noti- LESSONS LEARNED: A problem

fication, these suppliers made needs to be identified to find the true

modifications and showed signifi- root cause. Root cause analysis must

cant improvement. explore all aspects so an efficient and To learn more about ProTrans’ solutions

effective action plan may be deployed. call 317-240-4100 or visit www.protrans.com.

48 Inbound Logistics • April 2017

Got 3PL challenges? Get free expert solutions at inboundlogistics.com/3pl