Page 73 - Inbound Logistics | April 2017 | Digital Issue

P. 73

In addition, the system can help

make sure that each truck receives pre-

ventive maintenance as needed. Rather

than bringing in each truck every 30

days to change the oil, check fluid

levels, and perform other routine proce-

dures, TotalTrax can monitor distance

traveled, how many pallets the truck

lifted, and other factors to tailor the best

maintenance schedule for each vehicle.

Users also employ the system to

monitor productivity. The Advanced

Telematics Platform continually mea-

sures each truck’s activity, and an

optional sensor indicates when the fork-

lift is carrying a pallet.

Beyond simply calculating how much

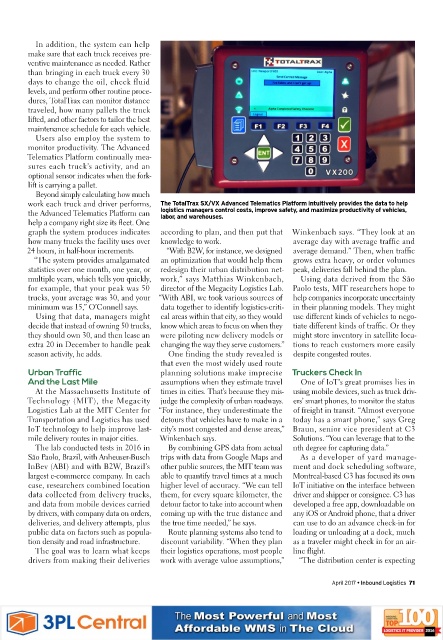

work each truck and driver performs, The TotalTrax SX/VX Advanced Telematics Platform intuitively provides the data to help

the Advanced Telematics Platform can logistics managers control costs, improve safety, and maximize productivity of vehicles,

labor, and warehouses.

help a company right size its fleet. One

graph the system produces indicates according to plan, and then put that Winkenbach says. “They look at an

how many trucks the facility uses over knowledge to work. average day with average traffic and

24 hours, in half-hour increments. “With B2W, for instance, we designed average demand.” Then, when traffic

“The system provides amalgamated an optimization that would help them grows extra heavy, or order volumes

statistics over one month, one year, or redesign their urban distribution net- peak, deliveries fall behind the plan.

multiple years, which tells you quickly, work,” says Matthias Winkenbach, Using data derived from the São

for example, that your peak was 50 director of the Megacity Logistics Lab. Paolo tests, MIT researchers hope to

trucks, your average was 30, and your “With ABI, we took various sources of help companies incorporate uncertainty

minimum was 15,” O’Connell says. data together to identify logistics-criti- in their planning models. They might

Using that data, managers might cal areas within that city, so they would use different kinds of vehicles to nego-

decide that instead of owning 50 trucks, know which areas to focus on when they tiate different kinds of traffic. Or they

they should own 30, and then lease an were piloting new delivery models or might store inventory in satellite loca-

extra 20 in December to handle peak changing the way they serve customers.” tions to reach customers more easily

season activity, he adds. One finding the study revealed is despite congested routes.

that even the most widely used route

Urban Traffic planning solutions make imprecise Truckers Check In

And the Last Mile assumptions when they estimate travel One of IoT’s great promises lies in

At the Massachusetts Institute of times in cities. That’s because they mis- using mobile devices, such as truck driv-

Technology (MIT), the Megacity judge the complexity of urban roadways. ers’ smart phones, to monitor the status

Logistics Lab at the MIT Center for “For instance, they underestimate the of freight in transit. “Almost everyone

Transportation and Logistics has used detours that vehicles have to make in a today has a smart phone,” says Greg

IoT technology to help improve last- city’s most congested and dense areas,” Braun, senior vice president at C3

mile delivery routes in major cities. Winkenbach says. Solutions. “You can leverage that to the

The lab conducted tests in 2016 in By combining GPS data from actual nth degree for capturing data.”

São Paolo, Brazil, with Anheuser-Busch trips with data from Google Maps and As a developer of yard manage-

InBev (ABI) and with B2W, Brazil’s other public sources, the MIT team was ment and dock scheduling software,

largest e-commerce company. In each able to quantify travel times at a much Montreal-based C3 has focused its own

case, researchers combined location higher level of accuracy. “We can tell IoT initiative on the interface between

data collected from delivery trucks, them, for every square kilometer, the driver and shipper or consignee. C3 has

and data from mobile devices carried detour factor to take into account when developed a free app, downloadable on

by drivers, with company data on orders, coming up with the true distance and any iOS or Android phone, that a driver

deliveries, and delivery attempts, plus the true time needed,” he says. can use to do an advance check-in for

public data on factors such as popula- Route planning systems also tend to loading or unloading at a dock, much

tion density and road infrastructure. discount variability. “When they plan as a traveler might check in for an air-

The goal was to learn what keeps their logistics operations, most people line flight.

drivers from making their deliveries work with average value assumptions,” “The distribution center is expecting

April 2017 • Inbound Logistics 71