Page 13 - IMER_2021-07_MPT_cat_en_Neat

P. 13

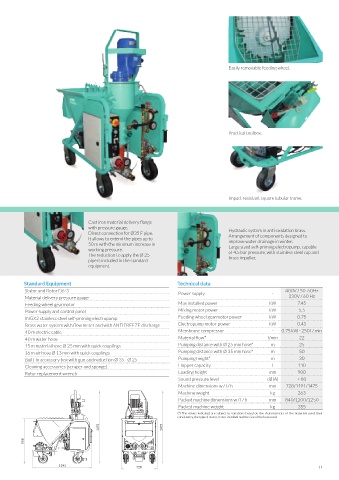

Easily removable feeding wheel.

Practical toolbox.

Impact resistant square tubular frame.

Cast iron material delivery flange

with pressure gauge.

Direct connection for Ø35 F pipe. Hydraulic system in anti-oxidation brass.

Arrangement of components designed to

It allows to extend the pipes up to improve water drainage in winter.

50 m with the minimum increase in Large sized self-priming electropump, capable

working pressure. of 4.5 bar pressure, with stainless steel cap and

The reduction to apply the Ø 25

pipe is included in the standard brass impeller.

equipment.

Standard Equipment Technical data

Stator and Rotor D6-3 400V / 50-60Hz

Power supply -

Material delivery pressure gauge 230V / 60 Hz

Feeding wheel gearmotor Max installed power kW 7.45

Power supply and control panel Mixing motor power kW 5.5

INGX2 stainless steel self-priming electropump Feeding wheel gearmotor power kW 0.75

Brass water system with flow meter and with ANTIFREEZE discharge Electropump motor power kW 0.45

40 m electric cable Membrane compressor - 0.75 kW - 250 l / min

40 m water hose Material flow* l/min 22

15 m material hose Ø 25 mm with quick couplings Pumping distance with Ø 25 mm hose* m 25

16 m air hose Ø 13 mm with quick couplings Pumping distance with Ø 35 mm hose* m 50

Built-in accessory box with gun and reduction Ø 35 - Ø 25 Pumping height* m 30

Cleaning accessories (scraper and sponge) Hopper capacity l 110

Rotor replacement wrench Loading height mm 900

Sound pressure level dB(A) < 80

Machine dimensions w / l / h mm 728/1191/1475

Machine weight kg 263

Packed machine dimensions w / l / h mm 840/1200/1250

Packed machine weight kg 355

(*) The values indicated are subject to variations based on the characteristics of the materials used, their

consistency, the type of stator / rotor installed and the size of the hose used.

1475 1475 1475 1475

908 908

1191

728 728 11

1191

PARTICOLARE

KOINE 4 220V 60 Hz

1106004 325.9 kg

CODICE MATERIALE PESO

Ing. Disabato

COD.MAT.PRIMA * DENOMINAZIONE APPROVATO

*

TOLLERANZE GENERALI ISO 2768 - mK TRATTAMENTO TERMICO 21/11/2017 SCALA

DATA CREAZIONE

DISEGNATORE

TRATTAMENTO SUPERFICIALE

1 23/04/2018 CID 116 MOD IMPIANTO ACQUA Borzi E. Ing. Disabato Disabato D. A2 FOGLIO DI 1 1

REV DATA DESCRIZIONE DISEGNATORE APPROVATO