Page 44 - catalog final tipar_Neat

P. 44

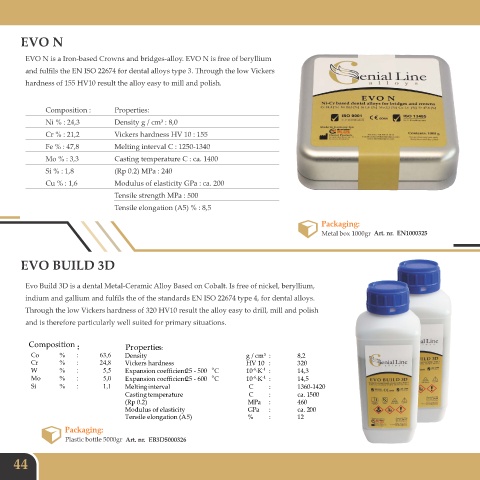

EVO N

EVO N is a Iron-based Crowns and bridges-alloy. EVO N is free of beryllium

and fulfils the EN ISO 22674 for dental alloys type 3. Through the low Vickers

hardness of 155 HV10 result the alloy easy to mill and polish.

Composition : Properties:

Ni % : 24,3 Density g / cm³ : 8,0

Cr % : 21,2 Vickers hardness HV 10 : 155

Fe % : 47,8 Melting interval C : 1250-1340

Mo % : 3,3 Casting temperature C : ca. 1400

Si % : 1,8 (Rp 0.2) MPa : 240

Cu % : 1,6 Modulus of elasticity GPa : ca. 200

Tensile strength MPa : 500

Tensile elongation (A5) % : 8,5

Packaging:

Metal box 1000gr Art. nr. EN1000325

EVO BUILD 3D

Evo Build 3D is a dental Metal-Ceramic Alloy Based on Cobalt. Is free of nickel, beryllium,

indium and gallium and fulfils the of the standards EN ISO 22674 type 4, for dental alloys.

Through the low Vickers hardness of 320 HV10 result the alloy easy to drill, mill and polish

and is therefore particularly well suited for primary situations.

Composition :

Properties:

Co % : 63,6 Density g / cm³ : 8,2

Cr % : 24,8 Vickers hardness HV 10 : 320

-1

-6

W % : 5,5 Expansion coefficient 25 - 500 °C 10 ·K : 14,3

-1

Mo % : 5,0 Expansion coefficient 25 - 600 °C 10 ·K : 14,5

-6

Si % : 1,1 Melting interval C : 1360-1420

Casting temperature C : ca. 1500

(Rp 0.2) MPa : 460

Modulus of elasticity GPa : ca. 200

Tensile elongation (A5) % : 12

Packaging:

Plastic bottle 5000gr Art. nr. EB3D5000326

44