Page 20 - TECHNICAL SPECIFICATION FOR PALM OIL REFINING_rev.1 - Copy_Float

P. 20

OFFER NO. KMIPL/P16E0097R7

100 TPD PHYSICAL REFINERY AND FRACTIONATION

Page No. 20/69

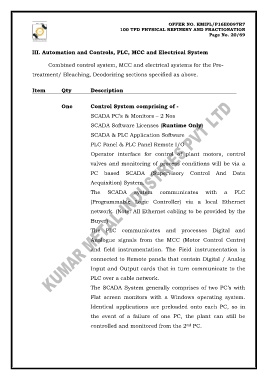

III. Automation and Controls, PLC, MCC and Electrical System

Combined control system, MCC and electrical systems for the Pre-

treatment/ Bleaching, Deodorizing sections specified as above.

Item Qty Description

One Control System comprising of -

SCADA PC’s & Monitors – 2 Nos

SCADA Software Licenses (Runtime Only)

SCADA & PLC Application Software

PLC Panel & PLC Panel Remote I/O

Operator interface for control of plant motors, control

valves and monitoring of process conditions will be via a

PC based SCADA (Supervisory Control And Data

Acquisition) System.

The SCADA system communicates with a PLC

(Programmable Logic Controller) via a local Ethernet

network. (Note: All Ethernet cabling to be provided by the

Buyer)

The PLC communicates and processes Digital and

Analogue signals from the MCC (Motor Control Centre)

and field instrumentation. The Field instrumentation is

connected to Remote panels that contain Digital / Analog

Input and Output cards that in turn communicate to the

PLC over a cable network.

The SCADA System generally comprises of two PC’s with

Flat screen monitors with a Windows operating system.

Identical applications are preloaded onto each PC, so in

the event of a failure of one PC, the plant can still be

controlled and monitored from the 2 PC.

nd