Page 17 - August_10th_SrSteerCo_e_bookwof

P. 17

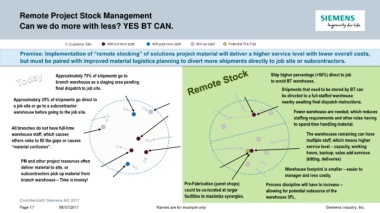

Remote Project Stock Management

Can we do more with less? YES BT CAN.

Customer Site WH full-time staff WH part-time staff WH no staff Potential Pre-Fab

Premise: Implementation of “remote stocking” of solutions project material will deliver a higher service level with lower overall costs,

but must be paired with improved material logistics planning to divert more shipments directly to job site or subcontractors.

Approximately 75% of shipments go to Ship higher percentage (>50%) direct to job

branch warehouse as a staging area pending to avoid BT warehouse.

final dispatch to job site. Shipments that need to be stored by BT can

be directed to a full-staffed warehouse

Approximately 25% of shipments go direct to nearby awaiting final dispatch instructions.

a job site or go to a subcontractor

warehouse before going to the job site. Fewer warehouse are needed, which reduces

staffing requirements and other roles having

to spend time handling material.

All branches do not have full-time

warehouse staff, which causes The warehouses remaining can have

others roles to fill the gaps or causes multiple staff, which means higher

“material confusion”. service level – capacity, working

hours, backup, value add services

(kitting, deliveries)

PM and other project resources often

deliver material to site, or Warehouse footprint is smaller – easier to

subcontractors pick up material from manager and less costly.

branch warehouse – Time is money!

Pre-Fabrication (panel shops) Process discipline will have to increase –

could be co-located at larger allowing for potential outsource of the

facilities to maximize synergies. warehouse 3PL.

Confidential© Siemens AG 2017

Page 17 08/07/2017 Names are for example only Siemens Industry, Inc.