Page 82 - demo

P. 82

PROBLEMS & ISSUES TO BE ADDRESSED

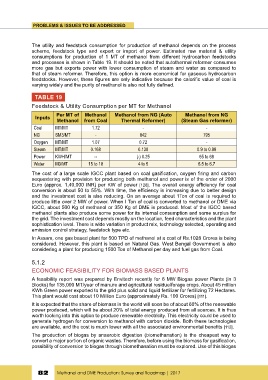

The utility and feedstock consumption for production of methanol depends on the process

scheme, feedstock type and export or import of power. Estimated raw material & utility

consumptions for production of 1 MT of methanol from different hydrocarbon feedstocks

and processes is shown in Table 19. It should be noted that autothermal reformer consumes

more gas but exports power with lower consumption of steam and water as compared to

that of steam reformer. Therefore, this option is more economical for gaseous hydrocarbon

feedstocks. However, these figures are only indicative because the calorific value of coal is

varying widely and the purity of methanol is also not fully defined.

TABLE 19

Feedstock & Utility Consumption per MT for Methanol

Per MT of Methanol Methanol from NG (Auto Methanol from NG

Inputs

Methanol from Coal Thermal Reformer) (Steam Gas reformer)

Coal MT/MT 1.72 - -

NG SM3/MT - 842 795

Oxygen MT/MT 1.07 0.72 -

Steam MT/MT 0.168 0.138 0.9 to 0.98

Power KWH/MT -- (-) 0.25 65 to 68

Water M3/MT 15 to 18 4 to 5 6.5 to 6.7

The cost of a large scale IGCC plant based on coal gasification, oxygen firing and carbon

sequestering with provision for producing both methanol and power is of the order of 2000

Euro (approx. 1,40,000 INR) per KW of power [126]. The overall energy efficiency for coal

conversion is about 50 to 55%. With time, the efficiency is increasing due to better design

and the investment cost is also reducing. On an average about 1Ton of coal is required to

produce little over 2 MW of power. When I Ton of coal is converted to methanol or DME via

IGCC, about 500 Kg of methanol or 350 Kg of DME is produced. Most of the IGCC based

methanol plants also produce some power for its internal consumption and some surplus for

the grid. The investment cost depends mostly on the location, feed characteristics and the plant

sophistication level. There is wide variation in product mix, technology selected, operating and

emission control strategy, feedstock type etc.

In Assam, one gas based plant for 500 TPD of methanol at a cost of Rs.1028 Crores is being

considered. However, this plant is based on Natural Gas. West Bengal Government is also

considering a plant for producing 1500 Ton of Methanol per day and fuel gas from Coal.

5.1.2

ECONOMIC FEASIBILITY FOR BIOMASS BASED PLANTS

A feasibility report was prepared by Envitech recently for 6 MW Biogas power Plants (in 3

Blocks) for 135,000 MT/year of manure and agricultural residue/forage crops. About 45 million

KWh Green power exported to the grid plus solid and liquid fertilizer for fertilizing 72 Hectares.

This plant would cost about 10 Million Euro (approximately Rs. 100 Crores) [111].

It is expected that the share of biomass in the world will soon be of about 60% of the renewable

power produced, which will be about 20% of total energy produced from all sources. It is thus

worth looking into this option to produce renewable electricity. This electricity could be used to

generate hydrogen for conversion to methanol with carbon dioxide. Both these technologies

are available, and the cost is much lower with all the associated environmental benefits [112].

The production of biogas by anaerobic digestion (biomethanation) is the cheapest way to

convert a major portion of organic wastes. Therefore, before using the biomass for gasification,

possibility of conversion to biogas through biomethanation must be explored. Use of this biogas

82 Methanol and DME Production: Survey and Roadmap | 2017