Page 45 - Jet Pumping Station

P. 45

The Bypass Pressure Regulating Valve prevents system pressure The bypass line should be as large as the ports of the

from exceeding a preset maximum. As the system approaches regulating valve. Do not install shutoff valves or other

this maximum pressure, excess fluid is bypassed (to a supply restrictions.

tank, or to the pump inlet). This prevents overpressurization and Install a high-quality industrial pressure gauge in the

system failures. discharge system to monitor system pressure. Failure to do

INSTALLATION so may result in overpressurization and premature failure of

Location pumping system components.

Install the regulating valve between the pump outlet (as For smoothest operation and minimal pressure spiking

close to the pump as possible) and any shut-off device in the when the discharge system is closed (closed gun, plugged

discharge plumbing. It may be located in the discharge line, or off- nozzles, valve closed), 10% of the rated flow of the

line: regulating valve should be bypassed at all times.

• If in-line, use either of the horizontal ports as the inlet and the EXAMPLE: With the C22A valve (rated to 10 gpm), 1

other as the outlet; gpm should be bypassing at all times during operation.

• If off-line, use either of the horizontal ports as the inlet and If the desired spray gun delivery is 6 gpm, then the

plug the other one. pump should deliver 7 gpm (6 gpm to the gun and 1

The bottom port is always the bypass port. gpm to be bypassed). The nozzle orifices should be

Mounting Position properly sized for 6 gpm delivery at the desired

The preferred mounting position is vertical with the adjusting bolt pressure; the pump RPM for 7 gpm; and the pump HP

at the top. for 7 gpm at the bypass pressure (bypass pressure is

Connections higher than nozzle pressure). [Bypass not required on

For best operation, the bypass line should return to the C22, C23, and C24 "AD" series valve]

supply tank. If you must plumb the bypass line back to the pump

inlet instead, have it enter the inlet line as far from the pump as PRESSURE ADJUSTMENT

possible. Contact the pump manufacturer, as a pressure regulator Systems with Shutoff Guns or Valves

may be required in the pump inlet. 1. Turn off the system.

2. Turn the adjusting nut counterclockwise until there is

no longer any pressure on the springs in the regulating

valve.

3. Close the discharge line.

4. Be sure the piping and all valves and nozzles are open.

With an accurate pressure gauge installed in the

system, start the system and let it run for a few minutes

to remove any air.

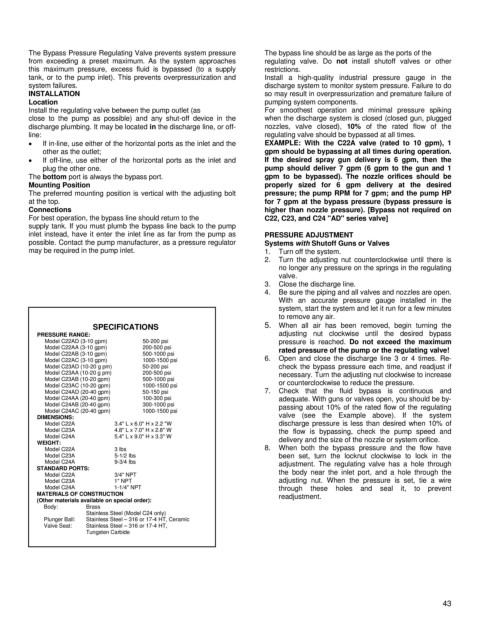

SPECIFICATIONS 5. When all air has been removed, begin turning the

PRESSURE RANGE: adjusting nut clockwise until the desired bypass

Model C22AD (3-10 gpm) 50-200 psi pressure is reached. Do not exceed the maximum

Model C22AA (3-10 gpm) 200-500 psi rated pressure of the pump or the regulating valve!

Model C22AB (3-10 gpm) 500-1000 psi

Model C22AC (3-10 gpm) 1000-1500 psi 6. Open and close the discharge line 3 or 4 times. Re-

Model C23AD (10-20 g pm) 50-200 psi check the bypass pressure each time, and readjust if

Model C23AA (10-20 g pm) 200-500 psi necessary. Turn the adjusting nut clockwise to increase

Model C23AB (10-20 gpm) 500-1000 psi or counterclockwise to reduce the pressure.

Model C23AC (10-20 gpm) 1000-1500 psi

Model C24AD (20-40 gpm) 50-150 psi 7. Check that the fluid bypass is continuous and

Model C24AA (20-40 gpm) 100-300 psi adequate. With guns or valves open, you should be by-

Model C24AB (20-40 gpm) 300-1000 psi passing about 10% of the rated flow of the regulating

Model C24AC (20-40 gpm) 1000-1500 psi

DIMENSIONS: valve (see the Example above). If the system

Model C22A 3.4" L x 6.0" H x 2.2 "W discharge pressure is less than desired when 10% of

Model C23A 4.8" L x 7.0" H x 2.8" W the flow is bypassing, check the pump speed and

Model C24A 5.4" L x 9.0" H x 3.3" W delivery and the size of the nozzle or system orifice.

WEIGHT:

Model C22A 3 Ibs 8. When both the bypass pressure and the flow have

Model C23A 5-1/2 Ibs been set, turn the locknut clockwise to lock in the

Model C24A 9-3/4 Ibs adjustment. The regulating valve has a hole through

STANDARD PORTS: the body near the inlet port, and a hole through the

Model C22A 3/4" NPT

Model C23A 1" NPT adjusting nut. When the pressure is set, tie a wire

Model C24A 1-1/4" NPT through these holes and seal it, to prevent

MATERIALS OF CONSTRUCTION readjustment.

(Other materials available on special order):

Body: Brass

Stainless Steel (Model C24 only)

Plunger Ball: Stainless Steel – 316 or 17-4 HT, Ceramic

Valve Seat: Stainless Steel – 316 or 17-4 HT,

Tungsten Carbide

43