Page 46 - Jet Pumping Station

P. 46

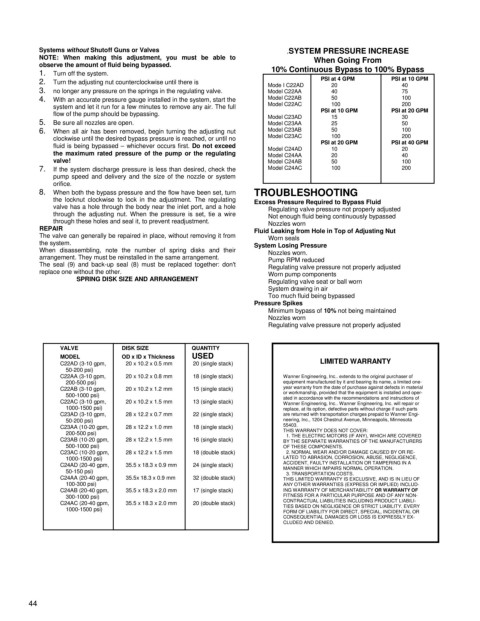

Systems without Shutoff Guns or Valves .SYSTEM PRESSURE INCREASE

NOTE: When making this adjustment, you must be able to When Going From

observe the amount of fluid being bypassed.

1. Turn off the system. 10% Continuous Bypass to 100% Bypass

2. Turn the adjusting nut counterclockwise until there is Mode I C22AD PSI at 4 GPM PSI at 10 GPM

40

20

3. no longer any pressure on the springs in the regulating valve. Model C22AA 40 75

4. With an accurate pressure gauge installed in the system, start the Model C22AB 50 100

system and let it run for a few minutes to remove any air. The full Model C22AC 100 200

flow of the pump should be bypassing. Model C23AD PSI at 10 GPM PSI at 20 GPM

30

15

5. Be sure all nozzles are open. Model C23AA 25 50

6. When all air has been removed, begin turning the adjusting nut Model C23AB 50 100

clockwise until the desired bypass pressure is reached, or until no Model C23AC 100 200

fluid is being bypassed – whichever occurs first. Do not exceed Model C24AD PSI at 20 GPM PSI at 40 GPM

10

20

the maximum rated pressure of the pump or the regulating Model C24AA 20 40

valve! Model C24AB 50 100

7. If the system discharge pressure is less than desired, check the Model C24AC 100 200

pump speed and delivery and the size of the nozzle or system

orifice.

8. When both the bypass pressure and the flow have been set, turn TROUBLESHOOTING

the locknut clockwise to lock in the adjustment. The regulating Excess Pressure Required to Bypass Fluid

valve has a hole through the body near the inlet port, and a hole Regulating valve pressure not properly adjusted

through the adjusting nut. When the pressure is set, tie a wire Not enough fluid being continuously bypassed

through these holes and seal it, to prevent readjustment. Nozzles worn

REPAIR Fluid Leaking from Hole in Top of Adjusting Nut

The valve can generally be repaired in place, without removing it from Worn seals

the system. System Losing Pressure

When disassembling, note the number of spring disks and their Nozzles worn.

arrangement. They must be reinstalled in the same arrangement. Pump RPM reduced

The seal (9) and back-up seal (8) must be replaced together: don't Regulating valve pressure not properly adjusted

replace one without the other. Worn pump components

SPRING DISK SIZE AND ARRANGEMENT Regulating valve seat or ball worn

System drawing in air

Too much fluid being bypassed

Pressure Spikes

Minimum bypass of 10% not being maintained

Nozzles worn

Regulating valve pressure not properly adjusted

VALVE DISK SIZE QUANTITY

MODEL OD x ID x Thickness USED LIMITED WARRANTY

C22AD (3-10 gpm, 20 x 10.2 x 0.5 mm 20 (single stack)

50-200 psi)

C22AA (3-10 gpm, 20 x 10.2 x 0.8 mm 18 (single stack) Wanner Engineering, Inc.. extends to the original purchaser of

200-500 psi) equipment manufactured by it and bearing its name, a limited one-

C22AB (3-10 gpm, 20 x 10.2 x 1.2 mm 15 (single stack) year warranty from the date of purchase against defects in material

or workmanship, provided that the equipment is installed and oper-

500-1000 psi)

C22AC (3-10 gpm, 20 x 10.2 x 1.5 mm 13 (single stack) ated in accordance with the recommendations and instructions of

Wanner Engineering, Inc.. Wanner Engineering, Inc. will repair or

1000-1500 psi) replace, at its option, defective parts without charge if such parts

C23AD (3-10 gpm, 28 x 12.2 x 0.7 mm 22 (single stack) are returned with transportation charges prepaid to Wanner Engi-

neering, Inc., 1204 Chestnut Avenue, Minneapolis, Minnesota

50-200 psi)

C23AA (10-20 gpm, 28 x 12.2 x 1.0 mm 18 (single stack) 55403.

200-500 psi) THIS WARRANTY DOES NOT COVER:

1. THE ELECTRIC MOTORS (IF ANY), WHICH ARE COVERED

C23AB (10-20 gpm, 28 x 12.2 x 1.5 mm 16 (single stack) BY THE SEPARATE WARRANTIES OF THE MANUFACTURERS

500-1000 psi)

C23AC (10-20 gpm, 28 x 12.2 x 1.5 mm 18 (double stack) OF THESE COMPONENTS.

2. NORMAL WEAR AND/OR DAMAGE CAUSED BY OR RE-

1000-1500 psi) LATED TO ABRASION, CORROSION, ABUSE, NEGLIGENCE,

C24AD (20-40 gpm, 35.5 x 18.3 x 0.9 mm 24 (single stack) ACCIDENT, FAULTY INSTALLATION OR TAMPERING IN A

MANNER WHICH IMPAIRS NORMAL OPERATION.

50-150 psi) 3. TRANSPORTATION COSTS.

C24AA (20-40 gpm, 35.5x 18.3 x 0.9 mm 32 (double stack) THIS LIMITED WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF

100-300 psi)

ANY OTHER WARRANTIES (EXPRESS OR IMPLIED) INCLUD-

C24AB (20-40 gpm, 35.5 x 18.3 x 2.0 mm 17 (single stack) ING WARRANTY OF MERCHANTABILITY OR WARRANTY OF

300-1000 psi) FITNESS FOR A PARTICULAR PURPOSE AND OF ANY NON-

CONTRACTUAL LIABILITIES INCLUDING PRODUCT LIABILI-

C24AC (20-40 gpm, 35.5 x 18.3 x 2.0 mm 20 (double stack) TIES BASED ON NEGLIGENCE OR STRICT LIABILITY. EVERY

1000-1500 psi) FORM OF LIABILITY FOR DIRECT, SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSS IS EXPRESSLY EX-

CLUDED AND DENIED.

44