Page 9 - Rocker Spin Clean

P. 9

ROCKER SPIN CLEAN

Installation

• The Rocker Spin Clean should be positioned in the tunnel leaving ample room for the enter switch.

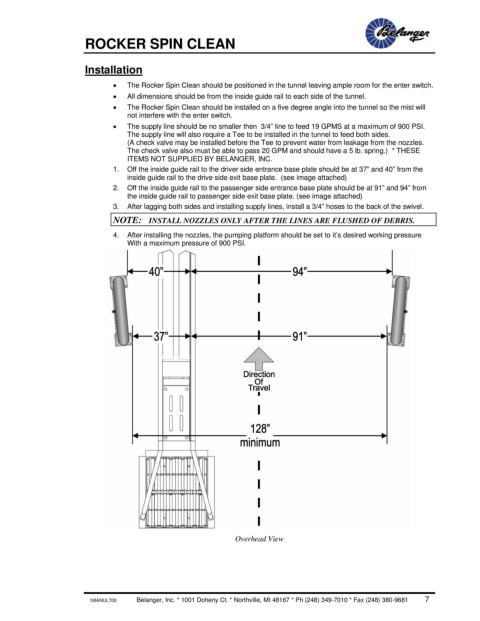

• All dimensions should be from the inside guide rail to each side of the tunnel.

• The Rocker Spin Clean should be installed on a five degree angle into the tunnel so the mist will

not interfere with the enter switch.

• The supply line should be no smaller then 3/4” line to feed 19 GPMS at a maximum of 900 PSI.

The supply line will also require a Tee to be installed in the tunnel to feed both sides.

(A check valve may be installed before the Tee to prevent water from leakage from the nozzles.

The check valve also must be able to pass 20 GPM and should have a 5 lb. spring.) * THESE

ITEMS NOT SUPPLIED BY BELANGER, INC.

1. Off the inside guide rail to the driver side entrance base plate should be at 37” and 40” from the

inside guide rail to the drive side exit base plate. (see image attached)

2. Off the inside guide rail to the passenger side entrance base plate should be at 91” and 94” from

the inside guide rail to passenger side exit base plate. (see image attached)

3. After lagging both sides and installing supply lines, install a 3/4” hoses to the back of the swivel.

NOTE: INSTALL NOZZLES ONLY AFTER THE LINES ARE FLUSHED OF DEBRIS.

4. After installing the nozzles, the pumping platform should be set to it’s desired working pressure

With a maximum pressure of 900 PSI.

Overhead View

1MANUL700 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 7