Page 4 - FreeStyler® Maintenance Manual

P. 4

®

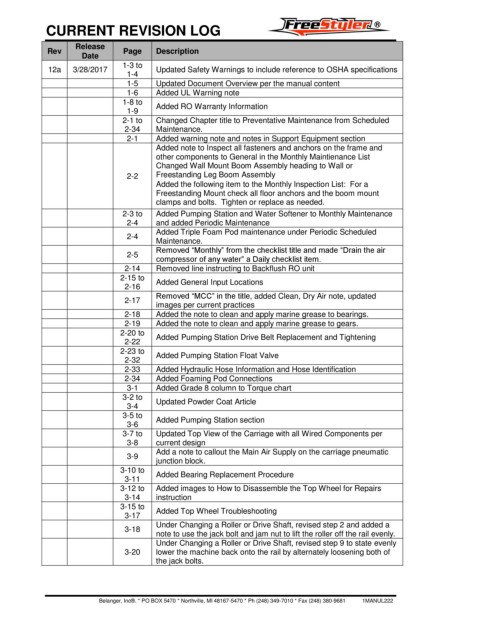

CURRENT REVISION LOG

Release

Rev Page Description

Date

1-3 to

12a 3/28/2017 Updated Safety Warnings to include reference to OSHA specifications

1-4

1-5 Updated Document Overview per the manual content

1-6 Added UL Warning note

1-8 to

Added RO Warranty Information

1-9

2-1 to Changed Chapter title to Preventative Maintenance from Scheduled

2-34 Maintenance.

2-1 Added warning note and notes in Support Equipment section

Added note to Inspect all fasteners and anchors on the frame and

other components to General in the Monthly Maintienance List

Changed Wall Mount Boom Assembly heading to Wall or

2-2 Freestanding Leg Boom Assembly

Added the following item to the Monthly Inspection List: For a

Freestanding Mount check all floor anchors and the boom mount

clamps and bolts. Tighten or replace as needed.

2-3 to Added Pumping Station and Water Softener to Monthly Maintenance

2-4 and added Periodic Maintenance

Added Triple Foam Pod maintenance under Periodic Scheduled

2-4

Maintenance.

Removed “Monthly” from the checklist title and made “Drain the air

2-5

compressor of any water” a Daily checklist item.

2-14 Removed line instructing to Backflush RO unit

2-15 to

Added General Input Locations

2-16

Removed “MCC” in the title, added Clean, Dry Air note, updated

2-17

images per current practices

2-18 Added the note to clean and apply marine grease to bearings.

2-19 Added the note to clean and apply marine grease to gears.

2-20 to

Added Pumping Station Drive Belt Replacement and Tightening

2-22

2-23 to

Added Pumping Station Float Valve

2-32

2-33 Added Hydraulic Hose Information and Hose Identification

2-34 Added Foaming Pod Connections

3-1 Added Grade 8 column to Torque chart

3-2 to

Updated Powder Coat Article

3-4

3-5 to

Added Pumping Station section

3-6

3-7 to Updated Top View of the Carriage with all Wired Components per

3-8 current design

Add a note to callout the Main Air Supply on the carriage pneumatic

3-9

junction block.

3-10 to

Added Bearing Replacement Procedure

3-11

3-12 to Added images to How to Disassemble the Top Wheel for Repairs

3-14 instruction

3-15 to

Added Top Wheel Troubleshooting

3-17

Under Changing a Roller or Drive Shaft, revised step 2 and added a

3-18

note to use the jack bolt and jam nut to lift the roller off the rail evenly.

Under Changing a Roller or Drive Shaft, revised step 9 to state evenly

3-20 lower the machine back onto the rail by alternately loosening both of

the jack bolts.

Belanger, Inc®. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL222