Page 17 - Crane and Rigging

P. 17

Inspect wire rope before use.

Check for evidence of severe kinking, crushing or heat damage.

Broken wires are normal on the outside of a strand. But if you find six or more broken wires within one

lay of strand length, the rope should be not be use.

Inspect other fittings to be used.

Do not use rigging gear with end fittings that are corroded, cracked, bent or improperly attached.

If more than one broken wire exists within one lay length of the end fitting, the sling should not be used.

Inspect shackles for load-lifting capacity and possible damage.

Replace any rope, sling or shackle if you have any doubts about its fitness for use.

SECURING THE LOAD

Cranes are designed for vertical lifts only. Side pulling and in pulling result in many hoist and crane

breakdowns. Improper lifts can cause the following:

• bend or break the cable guide

• jam the wire rope in the hoist housing

• damage the drum

• cause the chain or wire rope to break and suddenly drop the load.

When attaching slings to the load and hoist hook, pack corners and sharp edges to prevent cutting or

damaging the rope.

Determine the number of slings needed based on:

• the need to balance the load

• the weight of the load

• sling angles.

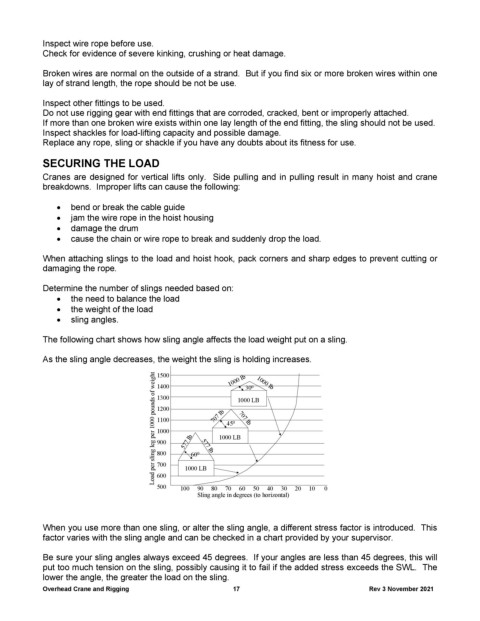

The following chart shows how sling angle affects the load weight put on a sling.

As the sling angle decreases, the weight the sling is holding increases.

1500 1000 lb 1000 lb

1400 30 0

1300 1000 LB

1200

1100 707 lb 0 707 lb

Load per sling leg per 1000 pounds of weight 1000 45

900 577 lb 1000 LB

577 lb

800 60 0

700 1000 LB

600

500 100 90 80 70 60 50 40 30 20 10 0

Sling angle in degrees (to horizontal)

When you use more than one sling, or alter the sling angle, a different stress factor is introduced. This

factor varies with the sling angle and can be checked in a chart provided by your supervisor.

Be sure your sling angles always exceed 45 degrees. If your angles are less than 45 degrees, this will

put too much tension on the sling, possibly causing it to fail if the added stress exceeds the SWL. The

lower the angle, the greater the load on the sling.

Overhead Crane and Rigging 17 Rev 3 November 2021