Page 4 - January 2019

P. 4

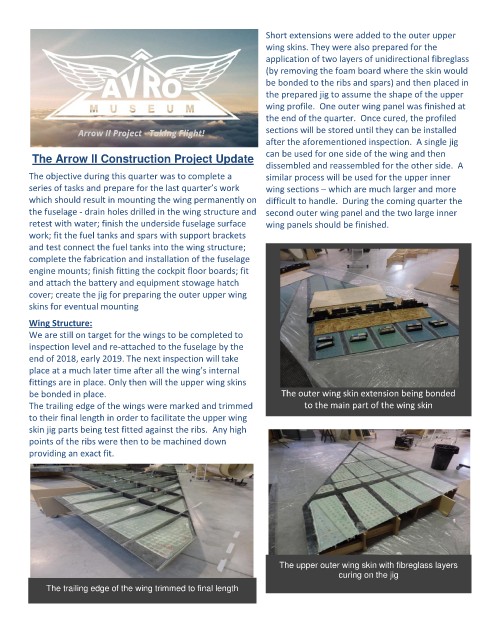

Short extensions were added to the outer upper

wing skins. They were also prepared for the

application of two layers of unidirectional fibreglass

(by removing the foam board where the skin would

be bonded to the ribs and spars) and then placed in

the prepared jig to assume the shape of the upper

wing profile. One outer wing panel was finished at

the end of the quarter. Once cured, the profiled

sections will be stored until they can be installed

after the aforementioned inspection. A single jig

The Arrow II Construction Project Update can be used for one side of the wing and then

dissembled and reassembled for the other side. A

The objective during this quarter was to complete a similar process will be used for the upper inner

series of tasks and prepare for the last quarter’s work wing sections – which are much larger and more

which should result in mounting the wing permanently on difficult to handle. During the coming quarter the

the fuselage - drain holes drilled in the wing structure and second outer wing panel and the two large inner

retest with water; finish the underside fuselage surface wing panels should be finished.

work; fit the fuel tanks and spars with support brackets

and test connect the fuel tanks into the wing structure;

complete the fabrication and installation of the fuselage

engine mounts; finish fitting the cockpit floor boards; fit

and attach the battery and equipment stowage hatch

cover; create the jig for preparing the outer upper wing

skins for eventual mounting

Wing Structure:

We are still on target for the wings to be completed to

inspection level and re-attached to the fuselage by the

end of 2018, early 2019. The next inspection will take

place at a much later time after all the wing’s internal

fittings are in place. Only then will the upper wing skins

be bonded in place. The outer wing skin extension being bonded

The trailing edge of the wings were marked and trimmed to the main part of the wing skin

to their final length in order to facilitate the upper wing

skin jig parts being test fitted against the ribs. Any high

points of the ribs were then to be machined down

providing an exact fit.

The upper outer wing skin with fibreglass layers

curing on the jig

The trailing edge of the wing trimmed to final length