Page 5 - January 2019

P. 5

The fuel tank mounting brackets were installed on some

of the spars late in the quarter. This was required prior

to similar brackets being attached to the tanks. Once in

place, the precise location of the fuel tank brackets will

be determined relative to the spar bracket locations and

the top wing skin. This process and the final fuel tank

fitting into the wing structure, complete with location

bolts and cushioning, will be completed before the wing

is attached to the fuselage. (See “Fuel Tanks” below.)

Undercarriage progress: Two boxes were constructed to

precisely fit the main undercarriage openings in the wing.

These will be used to confirm the mounting points for the

undercarriage systems prior to ordering the metal work The second engine mount strengthener

and undercarriage components late in the coming installed on the inside of the fuselage

quarter.

Fuselage:

The fuselage underside continued to receive finishing Fuel Tanks:

sanding, aided by the unit being rotated on its stand

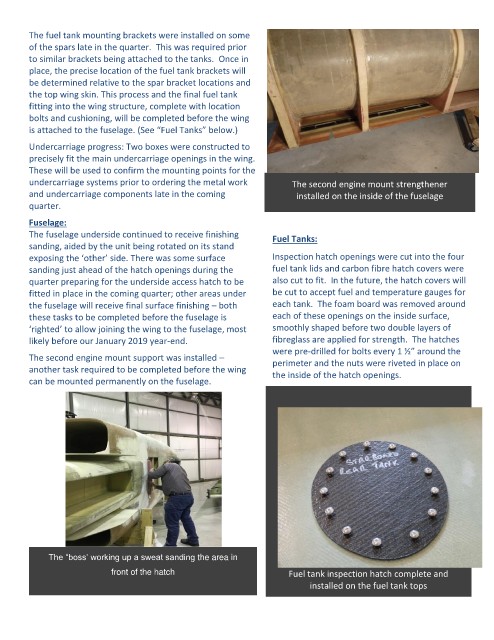

exposing the ‘other’ side. There was some surface Inspection hatch openings were cut into the four

sanding just ahead of the hatch openings during the fuel tank lids and carbon fibre hatch covers were

quarter preparing for the underside access hatch to be also cut to fit. In the future, the hatch covers will

fitted in place in the coming quarter; other areas under be cut to accept fuel and temperature gauges for

the fuselage will receive final surface finishing – both each tank. The foam board was removed around

these tasks to be completed before the fuselage is each of these openings on the inside surface,

‘righted’ to allow joining the wing to the fuselage, most smoothly shaped before two double layers of

likely before our January 2019 year-end. fibreglass are applied for strength. The hatches

were pre-drilled for bolts every 1 ½” around the

The second engine mount support was installed –

perimeter and the nuts were riveted in place on

another task required to be completed before the wing

the inside of the hatch openings.

can be mounted permanently on the fuselage.

The “boss’ working up a sweat sanding the area in

front of the hatch Fuel tank inspection hatch complete and

installed on the fuel tank tops