Page 15 - Wurth Total Catalogue

P. 15

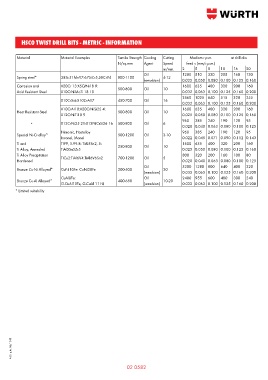

HSCO twiSt drill bitS - metriC - infOrmatiOn

Material Material Examples Tensile Strength Cooling Cutting Medium r.p.m. at drill dia.

N/sq.mm Agent Speed feed s (mm/r.p.m.)

m/min. 2 5 8 10 16 20

Oil 1280 510 320 255 160 130

Spring steel* 38Si:51MnV7:67SiCr5,58CrV4 800-1100 4-12

(emulsion) 0.025 0.050 0.080 0.100 0.125 0.160

Corrosion and X20Cr 13:X5CrNi18 9: 1600 635 400 320 200 160

Acid Resistant Steel X10CrNiMoTi 18 10 500-800 Oil 10 0.032 0.063 0.100 0.125 0.160 0.200

2560 1025 640 515 320 255

X10CrSi6:X10CrA17 450-700 Oil 16

0.032 0.063 0.100 0.125 0.160 0.200

X10CrAI18:X20CrNiSi25 4: 1600 635 400 320 200 160

Heat Resistant Steel 500-800 Oil 10

X12CrNiTi18 9 0.025 0.050 0.080 0.100 0.125 0.160

960 385 240 190 120 95

* X12CrNi25 21:X12NiCrSi36 16 500-800 Oil 6

0.020 0.040 0.063 0.080 0.100 0.125

Nimonic, Hastelloy 960 385 240 190 120 95

Special Ni-Cr-alloy* 500-1200 Oil 3-10

Inconel, Monel 0.022 0.045 0.071 0.090 0.112 0.143

Ti and Ti99, 5-99.8: TiAl5Sn2, 5: 350-800 Oil 10 1600 635 400 320 200 160

Ti Alloy, Annealed TiAl5Sn5Zr5 0.025 0.050 0.080 0.100 0.125 0.160

Ti Alloy Precipitation 800 320 200 160 100 80

Hardened TiCu2:TiAl6V4:TiAl6V6Sn2 700-1200 Oil 5 0.020 0.040 0.063 0.080 0.100 0.125

Oil 3200 1280 800 640 400 320

Bronze Cu-Ni Alloyed* CuNi10Fe: CuNi30Fe 300-500 20

(emulsion) 0.032 0.063 0.100 0.125 0.160 0.200

CuAl8Fe: Oil 2400 955 600 480 300 240

Bronze Cu-Al Alloyed* 400-650 10-20

G-CuAl10Fe, G-CuAl 11 Ni (emulsion) 0.032 0.063 0.100 0.125 0.160 0.200

* Limited suitability

AUS. pub. 06/10 ©

02 0582