Page 16 - Wurth Total Catalogue

P. 16

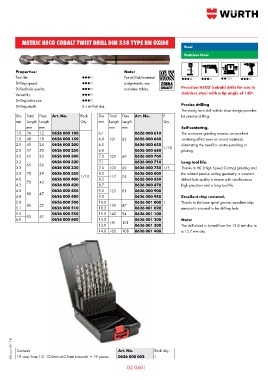

METRIC HSCO COBALT TWIST DRILL DIN 338 TYPE RN OXIDE

Steel

Stainless Steel

Properties: Note:

Tool life: ●●●○ For drill bit/material ●●●○ ●●●○ ●●○○ ●●●○

Drilling speed: ●●●○ assign ents see

Drilled-hole quality: ●●●○ overview tables. Precision HSCO (cobalt) drills for use in

o

Versatility: ●●●○ stainless steel with a tip angle of 130 .

Drilling behavior: ●●●○

Drilling depth: 5 x drill bit dia. Precise drilling

The sturdy twist drill with its short design provides

Dia. Total Flute Art. No. Pack Dia. Total Flute Art. No. P. for precise drilling.

mm Length Length Qty. mm Length Length Qty.

mm mm mm mm Self-centering.

1.0 34 12 0626 000 100 6.1 0626 000 610 The crosswise grinding ensures an excellent

1.5 40 18 0626 000 150 6.4 101 63 0626 000 640 centering effect even on round aterials

2.0 49 24 0626 000 200 6.5 0626 000 650 eliminating the need for centre-punching or

2.5 57 30 0626 000 250 6.8 0626 000 680 1/10 piloting.

3.0 61 33 0626 000 300 7.0 109 69 0626 000 700

3.2 0626 000 320 7.1 0626 000 710 Long tool life.

3.3 65 36 0626 000 330 7.5 109 69 0626 000 750 1/5 Thanks to HC (High Speed Cutting) grinding and

3.5 70 39 0626 000 350 8.0 0626 000 800 the related precise cutting geo etry a constant

4.0 0626 000 400 1/10 8.5 117 75 0626 000 850 drilled-hole quality is ensure with simultaneous

4.2 75 43 0626 000 420 8.7 0626 000 870 high precision and a long tool life.

4.5 0626 000 450 9.0 125 81 0626 000 900

4.8 80 47 0626 000 480 9.5 0626 000 950 Excellent chip removal.

5.0 0626 000 500 10.0 0626 001 000 1 Than s to the bare spiral groove excellent chip

5.1 86 52 0626 000 510 10.2 133 87 0626 001 020 removal is ensured in the drilling hole.

5.5 0626 000 550 11.0 142 94 0626 001 100

6.0 93 57 0626 000 600 12.0 0626 001 200 Note:

13.0 151 101 0626 001 300 The drill shank is turned from the 13.0 mm dia. to

14.0 160 108 0626 001 400 a 12.7 mm dia.

AUS. pub. 02/17 © Contents Art. No. Pack Qty.

0626 000 002

19 sizes from 1.0 - 10.0mm at 0.5mm intervals = 19 pieces.

1

02 0601