Page 93 - Wurth Total Catalogue

P. 93

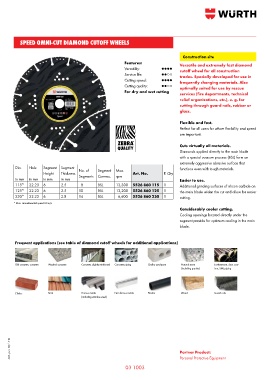

SPEED OMNI-CUT DIAMOND CUTOFF WHEELS

Construction site

Features: Versatile and extremely fast diamond

Versatility: ●●●● cutoff wheel for all construction

Service life: ●●○○ trades. Specially developed for use in

Cutting speed: ●●●● frequently changing materials. Also

Cutting quality: ●●○○ optimally suited for use by rescue

For dry and wet cutting services (fire departments, technical

relief organizations, etc.), e. g. for

cutting through guard rails, rubber or

glass.

Flexible and fast.

Perfect for all users for whom flexibility and speed

are important.

Cuts virtually all materials.

Diamonds applied directly to the main blade

with a special vacuum process (BSL) form an

extremely aggressive abrasive surface that

Dia. Hole Segment Segment functions even with tough materials.

Height Thickness No. of Segment Max. Art. No. P. Qty

Connec.

Segments

rpm

in mm in mm in mm in mm Easier to use.

115* 22.23 6 2.5 8 BSL 13,300 5526 860 115 1 Additional grinding surfaces of silicon carbide on

125* 22.23 6 2.5 10 BSL 12,200 5526 860 125 1 the main blade widen the cut and allow for easier

230* 22.23 6 2.8 16 BSL 6,600 5526 860 230 1 cutting.

* Max. circumferential speed 80 m/s

Considerably cooler cutting.

Cooling openings located directly under the

segment provide for optimum cooling in the main

blade.

Frequent applications (see table of diamond cutoff wheels for additional applications)

Old concrete, concrete Washed concrete Concrete, slightly reinforced Concrete piping Chalky sandstone Natural stone Earthenware, duct. cast-

(including granite) iron, SML piping

Clinker Brick Ferrous metals Non-ferrous metals Plastics Wood Guard rails

(including stainless steel)

AUS. pub. 02/17 © Partner Product:

Personal Protective Equipment

03 1003