Page 96 - Wurth Total Catalogue

P. 96

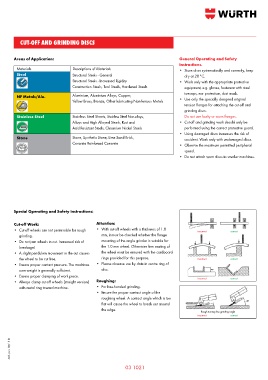

CUT-OFF AND GRINDING DISCS

Areas of Application: General Operating and Safety

Instructions.

Materials Descriptions of Materials • Store discs systematically and correctly, keep

Steel Structural Steels - General dry at 20°C.

Structural Steels - Increased Rigidity • Work only with the appropriate protective

Construction Steels, Tool Steels, Hardened Steels equipment, e.g. gloves, footwear with steel

NF Metals/Alu. Aluminium, Aluminium Alloys, Copper, toecaps, ear protection, dust mask.

Yellow Brass, Bronze, Other lubricating Non-ferrous Metals • Use only the specially designed original

tension flanges for attaching the cut-off and

grinding discs.

Stainless Steel Stainless Steel Sheets, Stainless Steel Non-alloys, Do not use faulty or worn flanges.

Alloys and High Alloyed Steels, Rust and • Cut-off and grinding work should only be

Acid Resistant Steels, Chromium Nickel Steels performed using the correct protective guard.

• Using damaged discs increases the risk of

Stone Stone, Synthetic Stone, Lime Sand Brick, accident. Work only with undamaged discs.

Concrete Reinforced Concrete • Observe the maximum permitted peripheral

speed.

• Do not attach worn discs to smaller machines.

Special Operating and Safety Instructions:

Cut-off Work: Attention:

• Cut-off wheels are not permissible for rough • With cut-off wheels with a thickness of 1.0 incorrect correct

grinding. mm, it must be checked whether the flange

• Do not jam wheels in cut. Increased risk of mounting of the angle grinder is suitable for

breakage! the 1.0 mm wheel. Otherwise firm seating of

• A slight pendulum movement in the cut causes the wheel must be ensured with the cardboard

the wheel to be cut free. rings provided for this purpose. incorrect correct

• Ensure proper contact pressure. The machines • Please observe use by date in centre ring of

own weight is generally sufficient. disc.

• Ensure proper clamping of work piece. incorrect correct

• Always clamp cut-off wheels (straight version) Roughing:

with metal ring toward machine. • For free-handed grinding.

• Ensure the proper contact angle of the

roughing wheel. A contact angle which is too

flat will cause the wheel to break out around

the edge.

Rough turning disc grinding angle

incorrect correct

AUS. pub. 08/16 ©

03 1021