Page 318 - Foton Workshop Manual - Tunland (AT)

P. 318

04-172 DIAGNOSTICS - ENGINE CONTROL SYSTEM

P234,P238,P239,P689,P731,P2321-CRANKSHAFT

POSITION SENSOR FAULT

P234-ENGINE CRANKSHAFT SPEED / POSITION - DATA IS VALID

BUT ABOVE NORMAL OPERATING RANGE - HIGHEST SEVERITY

04 LEVEL

P238-SENSOR POWER 3 CIRCUIT - VOLTAGE IS BELOW

NORMAL OR SHORTED TO LOW VOLTAGE POWER SUPPLY

P239-SENSOR POWER 3 CIRCUIT - VOLTAGE IS ABOVE NORMAL

OR SHORTED TO LOW VOLTAGE POWER SUPPLY

P689-ENGINE CRANKSHAFT SPEED / POSITION - DATA IS

UNSTABLE, INTERMITTENT OR INCORRECT

P731-ENGINE SPEED / POSITION CAMSHAFT AND CRANKSHAFT

ALIGNMENT ERRORS - MECHANICAL SYSTEMS ARE NOT

RESPONDING OR MISALIGNED

P2321-ENGINE CRANKSHAFT SPEED / POSITION - DATA IS

UNSTABLE, INTERMITTENT OR INCORRECT

Description

1 . The crankshaft position sensor is a Holzer effect sensor.The engine control

module (ECM) provides a 5V power to the position sensor through the sensor

power circuit. When the teeth on the crankshaft speed ring or the lobe at back

of the camshaft gear turns the sensor, the sensor generates a signal to be sent

to the ECM.The ECM identifies the signal and converts it to an engine speed

reading, and then determines the engine position according to the missing teeth

of the speed indicator ring.

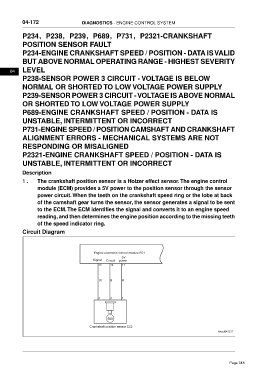

Circuit Diagram

Page 318