Page 60 - kursus eBook

P. 60

DRAFT GUIDELINE ON DOMESTIC GAS PIPING SYSTEM

PIPE PENETRATING THROUGH SOLID WALL

OR FLOOR

Non-Metallic Pipe Sleeve

Bare Copper Pipe

Gas

Brick/ R.C. Wall

FIG. 5 PIPE PENETRATING THROUGH SOLID WALL OR FLOOR

Underground pipe damage protection

Proper protective measures should be taken to protect underground gas piping against

damage caused by the third party work. In addition, when underground gas piping is

installed in soft soil, proper measures should be taken against differential settlements.

Underground gas piping installation before the boundary line of private land should have a

depth of cover not less than 900 mm.

Underground gas piping installation beyond the boundary line of private land should have a

depth of cover not less than 450 mm or deeper whichever is required by authority. The

cover should be permitted to be reduced to a minimum of 300 mm if external damage to the

pipe is not likely to result.

Pipe casing or protection slab should be used where the depth of cover of underground gas

piping is not sufficient to protect the pipe from damage.

For steel underground gas piping installation, a cathodic protection will be used in

conjunction with the coating to protect the gas pipe against corrosion.

Warning marker should be installed at suitable intervals along the straight and curved runs,

and whenever there is abrupt change in direction of the underground gas piping as required

by the regulations.

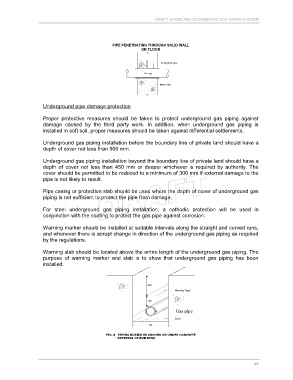

Warning slab should be located above the entire length of the underground gas piping. The

purpose of warning marker and slab is to show that underground gas piping has been

installed.

300

Warning Tape

150

Gas pipe

Copper Gas

Sand

450

FIG. 8 PIPING BURIED IN GROUND OR UNDER CONCRETE

EXTERNAL OF BUILDING

20