Page 60 - Personal Study Notes (Engineering Metrology - 22342)

P. 60

Page 60 of 176

1. According to the Type:

According to the type and principle of manufacturing the gauges may be classified as:

(a) Standard gauges,

(b) Limit gauges,

(c) Indicating gauges, and

(d) Combination gauges.

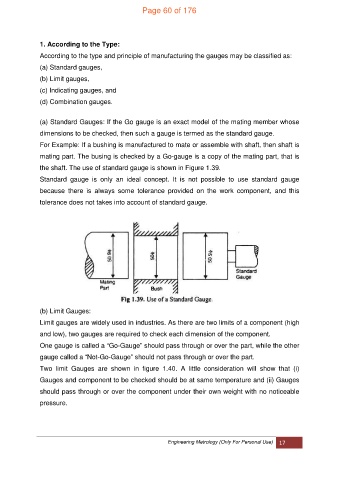

(a) Standard Gauges: If the Go gauge is an exact model of the mating member whose

dimensions to be checked, then such a gauge is termed as the standard gauge.

For Example: If a bushing is manufactured to mate or assemble with shaft, then shaft is

mating part. The busing is checked by a Go-gauge is a copy of the mating part, that is

the shaft. The use of standard gauge is shown in Figure 1.39.

Standard gauge is only an ideal concept. It is not possible to use standard gauge

because there is always some tolerance provided on the work component, and this

tolerance does not takes into account of standard gauge.

(b) Limit Gauges:

Limit gauges are widely used in industries. As there are two limits of a component (high

and low), two gauges are required to check each dimension of the component.

One gauge is called a “Go-Gauge” should pass through or over the part, while the other

gauge called a “Not-Go-Gauge” should not pass through or over the part.

Two limit Gauges are shown in figure 1.40. A little consideration will show that (i)

Gauges and component to be checked should be at same temperature and (ii) Gauges

should pass through or over the component under their own weight with no noticeable

pressure.

Engineering Metrology (Only For Personal Use) 17