Page 28 - Phelan Energy Green Ammonia Plant Egypt

P. 28

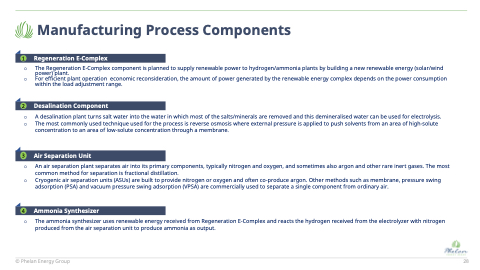

Manufacturing Process Components

1 Regeneration E-Complex

o The Regeneration E-Complex component is planned to supply renewable power to hydrogen/ammonia plants by building a new renewable energy (solar/wind power) plant.

o For efficient plant operation economic reconsideration, the amount of power generated by the renewable energy complex depends on the power consumption within the load adjustment range.

2 Desalination Component

o A desalination plant turns salt water into the water in which most of the salts/minerals are removed and this demineralised water can be used for electrolysis. o The most commonly used technique used for the process is reverse osmosis where external pressure is applied to push solvents from an area of high-solute

concentration to an area of low-solute concentration through a membrane.

3 Air Separation Unit

o An air separation plant separates air into its primary components, typically nitrogen and oxygen, and sometimes also argon and other rare inert gases. The most common method for separation is fractional distillation.

o Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon. Other methods such as membrane, pressure swing adsorption (PSA) and vacuum pressure swing adsorption (VPSA) are commercially used to separate a single component from ordinary air.

4 Ammonia Synthesizer

o The ammonia synthesizer uses renewable energy received from Regeneration E-Complex and reacts the hydrogen received from the electrolyzer with nitrogen

produced from the air separation unit to produce ammonia as output.

© Phelan Energy Group 28