Page 1137 - Adams and Stashak's Lameness in Horses, 7th Edition

P. 1137

Foot Care and Farriery 1103

VetBooks.ir

Figure 11.18. A wide‐web shoe with a concave solar surface

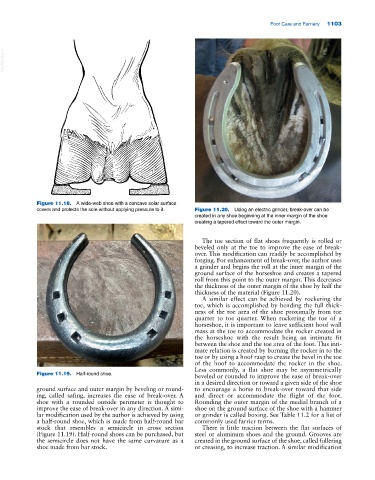

covers and protects the sole without applying pressure to it. Figure 11.20. Using an electric grinder, break‐over can be

created in any shoe beginning at the inner margin of the shoe

creating a tapered effect toward the outer margin.

The toe section of flat shoes frequently is rolled or

beveled only at the toe to improve the ease of break‐

over. This modification can readily be accomplished by

forging. For enhancement of break‐over, the author uses

a grinder and begins the roll at the inner margin of the

ground surface of the horseshoe and creates a tapered

roll from this point to the outer margin. This decreases

the thickness of the outer margin of the shoe by half the

thickness of the material (Figure 11.20).

A similar effect can be achieved by rockering the

toe, which is accomplished by bending the full thick

ness of the toe area of the shoe proximally from toe

quarter to toe quarter. When rockering the toe of a

horseshoe, it is important to leave sufficient hoof wall

mass at the toe to accommodate the rocker created in

the horseshoe with the result being an intimate fit

between the shoe and the toe area of the foot. This inti

mate relation is created by burning the rocker in to the

toe or by using a hoof rasp to create the bevel in the toe

of the hoof to accommodate the rocker in the shoe.

Less commonly, a flat shoe may be asymmetrically

Figure 11.19. Half‐round shoe. beveled or rounded to improve the ease of break‐over

in a desired direction or toward a given side of the shoe

ground surface and outer margin by beveling or round to encourage a horse to break‐over toward that side

ing, called safing, increases the ease of break‐over. A and direct or accommodate the flight of the foot.

shoe with a rounded outside perimeter is thought to Rounding the outer margin of the medial branch of a

improve the ease of break‐over in any direction. A simi shoe on the ground surface of the shoe with a hammer

lar modification used by the author is achieved by using or grinder is called boxing. See Table 11.2 for a list of

a half‐round shoe, which is made from half‐round bar commonly used farrier terms.

stock that resembles a semicircle in cross section There is little traction between the flat surfaces of

(Figure 11.19). Half‐round shoes can be purchased, but steel or aluminum shoes and the ground. Grooves are

the semicircle does not have the same curvature as a created in the ground surface of the shoe, called fullering

shoe made from bar stock. or creasing, to increase traction. A similar modification