Page 14 - Equipment Echoes Issue #137

P. 14

Excavating for Profit:

THE SAUERMAN SLACKLINE

CABLEWAY EXCAVATORS

By Thomas Berry

Author’s note: The text and, unless otherwise indicated, the images for this article are adapted from

two Sauerman Bros. catalogs, Excavating for Profit (No. 9, 1926) and Power Drag Scrapers (No. 14,

1931), in the HCEA Archives.

Serial No. 41,840, on May 14, 1918. The “Serial Numbers” were

A 1-yard Slackline Dragline bucket assigned to the original application, the patent numbers on award

brings in a load of wet gravel. of the patents.

Unfortunately, Sauerman rarely if ever included publication

dates on its literature. But a catalog containing citations of

Introduction machine installations in 1912 and 1913 and evidently published

Introduced in 1911, the Sauerman Bros. Slackline Cableway soon afterward is titled The Shearer & Mayer Dragline Cableway

Excavator gained acceptance from contractors, engineers and Excavators, with Sauerman Bros. cited as the “engineers and

aggregate producers for four main reasons: It excavated to great selling agents.”

depth equally well in dry ground or under water; it conveyed the

spoil over a great distance; it elevated the spoil to the hopper or

spoil bank; and because one simple machine with one operator

performed all this work. It could also handle odd assignments such

as backfilling behind a retaining wall that would have been more

costly by other means.

The exact story of the machine’s introduction is a bit sketchy,

but it is known that Henry B. Sauerman of Chicago, applied for a

patent for it on July 26, 1915, with one half of the patent assigned Two Slackline Dragline buckets for special applications, a small bucket for hard material at

to Jesse A. Shearer of Indianapolis. Two patents were awarded: left and a bucket for reclaiming aggregate from under water at right.

1171893, Serial No. 41, 841 on February 15, 1916, and 1265963,

Concept

The Slackline Cableway Excavator was primarily a long-range

machine, and was at its best working to considerable depths and

conveying at least 200 feet to an elevated dumping point. The most

efficient operating span between the mast and ground anchorages

varied with machine capacity; the smallest, with a 1/3-yard

bucket, worked most economically at about 300 feet, and the top

of the line 3½ yarder worked at lowest cost per yard at up to 1,200

feet. At times these ideal ranges had to be exceeded due to ground

conditions and obstructions such as rivers. Maximum effective

digging depth was one third the operating span, meaning it could

dig far deeper than was ever normally required.

It would elevate the load as high as the top of the mast. Many

aggregate producers used it to reach material 80 to 100 feet under

water and lift it 100 feet above the water’s surface to a hopper at

the edge of the pit. It would dig any material that could be turned

by an ordinary plow. Working to 100 feet deep with a 1,200 foot

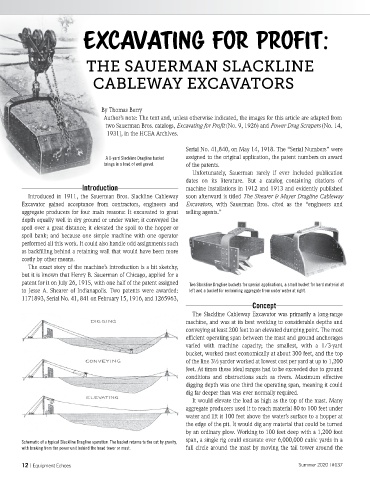

Schematic of a typical Slackline Dragline operation. The bucket returns to the cut by gravity, span, a single rig could excavate over 6,000,000 cubic yards in a

with braking from the power unit behind the head tower or mast. full circle around the mast by moving the tail tower around the

12 | Equipment Echoes Summer 2020 | #137