Page 17 - Equipment Echoes Issue #137

P. 17

Sauerman Slackline Cableway Excavators

Precision in dumping wasn’t always required when loading a car. Spoil fell against this

sloped dump board, allowing for faster operation. (Sauerman Bros. catalog, Shearar &

Mayer Dragline Cable Excavators, n. d., HCEA Archives)

But again, one operator ran everything, and help was needed only

for steam power, which required a fireman.

Power requirements varied with capacity. A one-yard machine

needed 200 pounds of coal, 30 kilowatts of electricity, eight gallons

of gas or six gallons of diesel fuel per hour.

Output

A slackline excavator’s output was usually not a constant due

to variances in length of haul and consistency of digging. But

Sauerman did note three rules of thumb that applied to estimating

production:

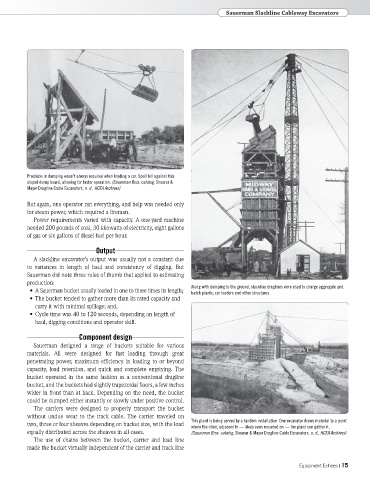

• A Sauerman bucket usually loaded in one to three times its length; Along with dumping to the ground, slackline draglines were used to charge aggregate and

batch plants, car loaders and other structures.

• The bucket tended to gather more than its rated capacity and

carry it with minimal spillage; and,

• Cycle time was 40 to 120 seconds, depending on length of

haul, digging conditions and operator skill.

Component design

Sauerman designed a range of buckets suitable for various

materials. All were designed for fast loading through great

penetrating power, maximum efficiency in loading to or beyond

capacity, load retention, and quick and complete emptying. The

bucket operated in the same fashion as a conventional dragline

bucket, and the buckets had slightly trapezoidal floors, a few inches

wider in front than at back. Depending on the need, the bucket

could be dumped either instantly or slowly under positive control.

The carriers were designed to properly transport the bucket

without undue wear to the track cable. The carrier traveled on

two, three or four sheaves depending on bucket size, with the load This plant is being served by a tandem installation. One excavator draws material to a point

where the other, adjacent to — likely even mounted on — the plant can gather it.

equally distributed across the sheaves in all cases. (Sauerman Bros. catalog, Shearar & Mayer Dragline Cable Excavators, n. d., HCEA Archives)

The use of chains between the bucket, carrier and load line

made the bucket virtually independent of the carrier and track line

Equipment Echoes | 15