Page 21 - Equipment Echoes Issue #137

P. 21

Sauerman Slackline Cableway Excavators

This is a Sauerman Crescent Hydraulic Scraper for tractor use. The Power Drag Scraper’s

bucket design is readily apparent. (Sauerman Bros. Catalog 18, 1936, HCEA Archives)

A tower machine with the operator’s compartment up top is digging a flood control reservoir

and placing the spoil on the slope of an impounding dam.

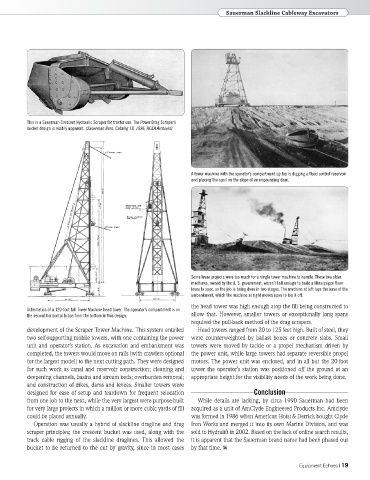

Some levee projects were too much for a single tower machine to handle. These two older

machines, owned by the U. S. government, weren’t tall enough to build a Mississippi River

levee to spec, so the job is being done in two stages. The machine at left lays the base of the

embankment, which the machine at right moves upon to top it off.

the head tower was high enough atop the fill being constructed to

Schematics of a 120-foot tall Tower Machine head tower. The operator’s compartment is on

the second horizontal brace from the bottom in this design. allow that. However, smaller towers or exceptionally long spans

required the pull-back method of the drag scrapers.

development of the Scraper Tower Machine. This system entailed Head towers ranged from 20 to 125 feet high. Built of steel, they

two self-supporting mobile towers, with one containing the power were counterweighted by ballast boxes or concrete slabs. Small

unit and operator’s station. As excavation and embankment was towers were moved by tackle or a propel mechanism driven by

completed, the towers would move on rails (with crawlers optional the power unit, while large towers had separate reversible propel

for the largest model) to the next cutting path. They were designed motors. The power unit was enclosed, and in all but the 20-foot

for such work as canal and reservoir construction; cleaning and tower the operator’s station was positioned off the ground at an

deepening channels, basins and stream beds; overburden removal; appropriate height for the visibility needs of the work being done.

and construction of dikes, dams and levees. Smaller towers were

designed for ease of setup and teardown for frequent relocation Conclusion

from one job to the next, while the very largest were purpose-built While details are lacking, by circa 1990 Sauerman had been

for very large projects in which a million or more cubic yards of fill acquired as a unit of AmClyde Engineered Products Inc. Amclyde

could be placed annually. was formed in 1986 when American Hoist & Derrick bought Clyde

Operation was usually a hybrid of slackline dragline and drag Iron Works and merged it into its own Marine Division, and was

scraper principles; the crescent bucket was used, along with the sold to Hydralift in 2002. Based on the lack of online search results,

track cable rigging of the slackline draglines. This allowed the it is apparent that the Sauerman brand name had been phased out

bucket to be returned to the cut by gravity, since in most cases by that time.

Equipment Echoes | 19